Designing a High-Density Interconnect (HDI) PCB requires a deep understanding of both electrical needs and manufacturing limits. HDI technology allows for more components in a smaller space. This makes it the top choice for modern electronics like smartphones and wearable tech.

Below is a detailed guide on the factors you must consider and how to optimize your HDI designs.

Factors to Consider During HDI PCB Design

1. Smart Component Selection

When you design an HDI board, you usually work with very small parts. This includes Surface Mount Devices (SMDs) and Ball Grid Arrays (BGAs) with a pitch of $0.65\text{ mm}$ or less.

You must choose your components carefully. The distance between the pins (the pitch) is the most important factor. If the pins are very close together, you will have less room to run your copper traces. This choice also tells you what kind of trace width you need and what type of via (hole) you must use. If you pick a BGA with a very small pitch, you might be forced to use more layers or smaller microvias to connect all the signals.

2. The Use of Microvias

Microvias are the heart of HDI design. These are very small holes, usually less than $0.15\text{ mm}$ in diameter. Designers often use “build-up” or “sequential” laminating techniques to create these holes.

Microvias help you save a lot of space. Because they are so small, you can fit more of them in a small area compared to traditional through-holes. Another big plus is their low inductance. This makes them perfect for high-speed circuits. You can use them to connect power planes to decoupling capacitors or in any place where you need to reduce electrical noise.

3. Material Selection

Choosing the right material is vital for any PCB, but it is even more critical for HDI. Your goal is to find a material that is easy to manufacture but also handles heat and electricity well.

The physical thickness of the material is a key factor. You need to look at the “aspect ratio” of the microvias. This is the ratio between the depth of the hole and its diameter. If the material is too thick and the hole is too small, it is very hard to plate the hole with copper properly. You must pick a material that allows the chemicals to flow through the holes during the plating process.

4. Via Capping and Offset Microvias

In HDI design, you can use a technique called “via-in-pad.” This means you place a microvia directly in the center of a surface mount pad.

To do this, the via must be “capped” or filled and then plated over with copper. This creates a flat surface for soldering. Using this method gives you much more room to route traces because the via does not take up extra space outside the pad. You can also use “offset” microvias, where the holes in different layers do not line up perfectly, to manage space even better.

5. Reduced Plane Perforations

When you design the power and ground planes under a BGA, you want as much solid copper as possible. This is called “Power Integrity” (PI).

In traditional designs, large through-holes create many “voids” or empty spots in the copper planes. This acts like a fence that blocks the flow of current. In HDI, because the vias are much smaller, you leave more copper intact. This improves the Electromagnetic Compatibility (EMC) of the board. It also provides better shielding against interference.

6. Stack-up and Delamination Issues

The “stack-up” is the arrangement of copper and insulation layers. In HDI, you often use different materials for different layers.

Every material has a “Coefficient of Thermal Expansion” (CTE). This tells you how much the material grows when it gets hot. If two layers have very different CTE values, they will expand at different rates. This can cause the layers to pull apart, which is called “delamination.” To avoid this, designers should try to use the same material for every layer or use materials with very similar CTE values and moisture absorption rates.

7. Testing Methods

Traditional “In-Circuit Testing” (ICT) is often not possible for HDI boards. ICT requires large test points that take up too much space.

Instead, designers use functional testing or JTAG (Joint Test Action Group) methods. JTAG allows you to test the connections between integrated circuits without needing physical test probes for every single wire. While ICT is very good at finding specific faults, JTAG is much better for the dense environment of an HDI board.

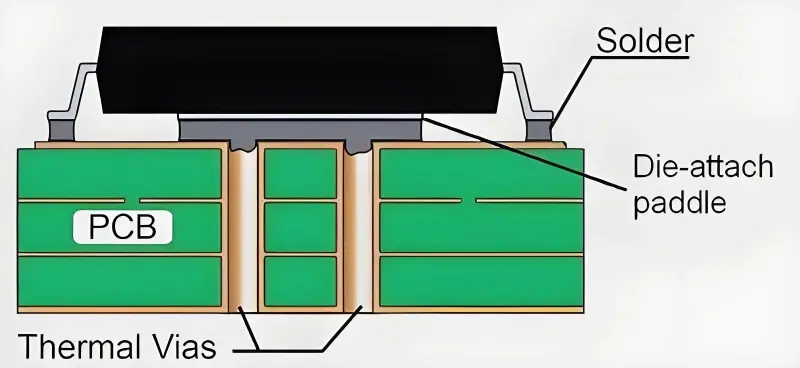

8. Thermal Management

HDI boards are very dense, so they get hot quickly. You must plan how to move heat away from the components.

You should follow the IPC-2226 standard, which provides rules for thermal design in HDI. One advantage of HDI is that the dielectric (insulation) layers are very thin. Thin layers, combined with microvias, actually help conduct heat away from the chips. If you have a very hot component, you can add “thermal vias” to move the heat to a larger copper plane or a heat sink.

9. Routing Demand vs. Substrate Capacity

“Routing demand” is the total length of all the wires needed to connect the parts on your board. “Substrate capacity” is the total length of wires that the board can actually hold.

For a successful design, the capacity must be higher than the demand. If your demand is too high, you might need to add more layers, but this increases the cost. Designers try to balance these two things to finish the design at the lowest possible cost.

10. Calculating PWB Density

You can measure how complex your design is by calculating the PWB (Printed Wiring Board) density. We measure this as the average length of traces per square inch.

To find this, we assume that each “net” (a single electrical connection) has three nodes and that each component lead is one node. We use the following formula:

$$Wd = \beta \sqrt{Cd \times Cc}$$

Kde:

- $Wd$: The PWB density (average trace length per square inch).

- $Cd$: Component Density (the average number of parts per square inch).

- $Cc$: Component Complexity (the average number of leads/pins per part).

- $\beta$: A constant based on the type of circuit.

- Use 2.5 for high-analog or discrete areas.

- Use 3.0 for mixed analog and digital areas.

- Use 3.5 for pure digital or ASIC areas.

This formula is a helpful guide. However, remember that every design is unique, and there is no single rule that fits every board.

How to Optimize Your HDI Design for Electronics

HDI is the fastest-growing part of the PCB industry. It makes boards more efficient and allows for faster signal speeds. Compared to standard boards, HDI boards have much thinner lines, smaller spaces, and smaller pads. The main difference is how the layers connect. Standard boards use holes that go all the way through, but HDI boards use blind and buried vias.

Here are several ways to optimize your design and avoid expensive mistakes.

Choose the Right Via Type

The vias you choose will change the performance and the cost of your board. Using microvias (blind or buried) can actually reduce the total number of layers you need. When you have fewer layers, your material costs go down. It also makes the manufacturing process less complex. You should talk to your manufacturer early to see which via types they can make reliably.

Select Components with Care

When you build an HDI board, you must be very careful about the parts you pick. Before you start the layout, look at the pin count and the size of the parts. Think about how the traces will fit between the pins. If you pick parts that are too complex for your board size, you will spend more time on the design and more money on manufacturing.

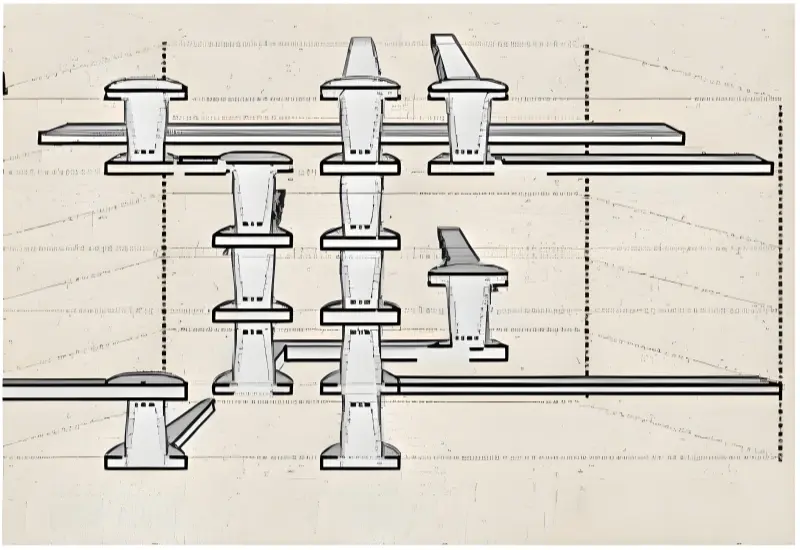

Plan the Stack-up Carefully

There are many ways to arrange the layers in an HDI board. Common styles include:

- 1-HDI: One layer of microvias on the top and bottom with a core containing buried vias.

- 2-HDI (Non-stacked): Two layers of microvias that do not sit on top of each other.

- Stacked 2-HDI: Microvias that sit directly on top of each other. These can be filled with resin or copper.

You must choose a stack-up that is balanced. If the stack-up is not symmetrical, the board might warp or bend during the heating process. A good stack-up improves the “yield” (the percentage of good boards made).

Use Proper Spacing

If you put components too close together, you might cause “Electromagnetic Interference” (EMI). This happens when the electrical signals from one wire leak into another wire. It can also create “parasitic capacitance,” which slows down your signals.

You should space your components to minimize stress and EMI. At the same time, make sure there is enough room for assembly and repair. If parts are too close, it is very hard to solder them or fix them if something goes wrong.

Focus on Signal Integrity (SI)

Signal Integrity is about making sure the electrical signal stays clean from one end of the wire to the other. To keep your signals strong:

- Keep the “aspect ratio” of your vias correct so the copper plating is thick and even.

- Use very small microvias to reduce the “stub” length (extra copper that hangs off a trace).

- Place small parts near each other to keep the signal paths short.

- Spread out buried and blind vias to reduce physical stress on the board materials.

Use Advanced Design Tools

Designing an HDI PCB is too hard for basic software. Manufacturers and designers need professional CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. They also use “Laser Direct Imaging” (LDI) to draw the tiny lines on the board. Because the tolerances are so small, the experience of the operator is just as important as the machines.

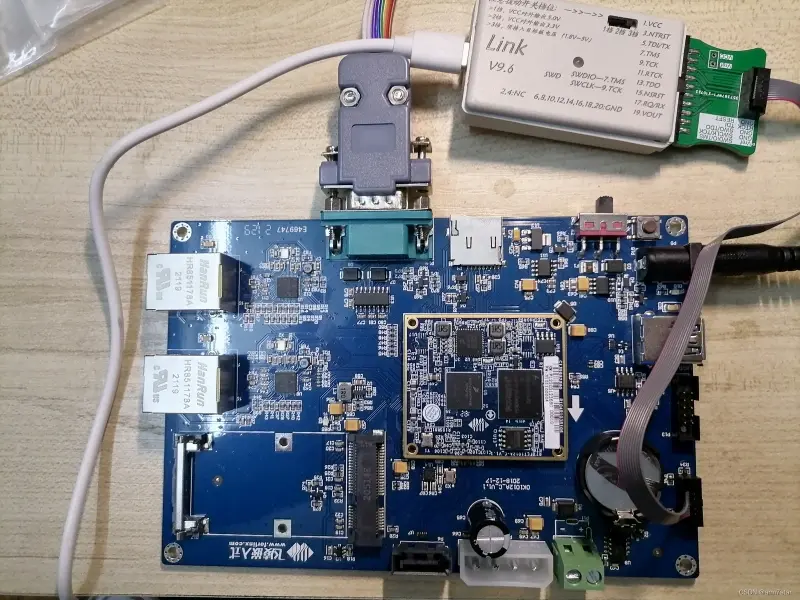

Benefits Across Industries

HDI boards are used because they make electronics perform better. You can find them in:

- Computers: For faster data processing.

- Smartphones: To fit more features in a pocket-sized device.

- Medical Devices: To make equipment smaller and more portable for doctors.

The success of your HDI project depends on how well you plan the layout and how well you work with your manufacturer. By following these tips, you can create a high-performance board that is both reliable and cost-effective.