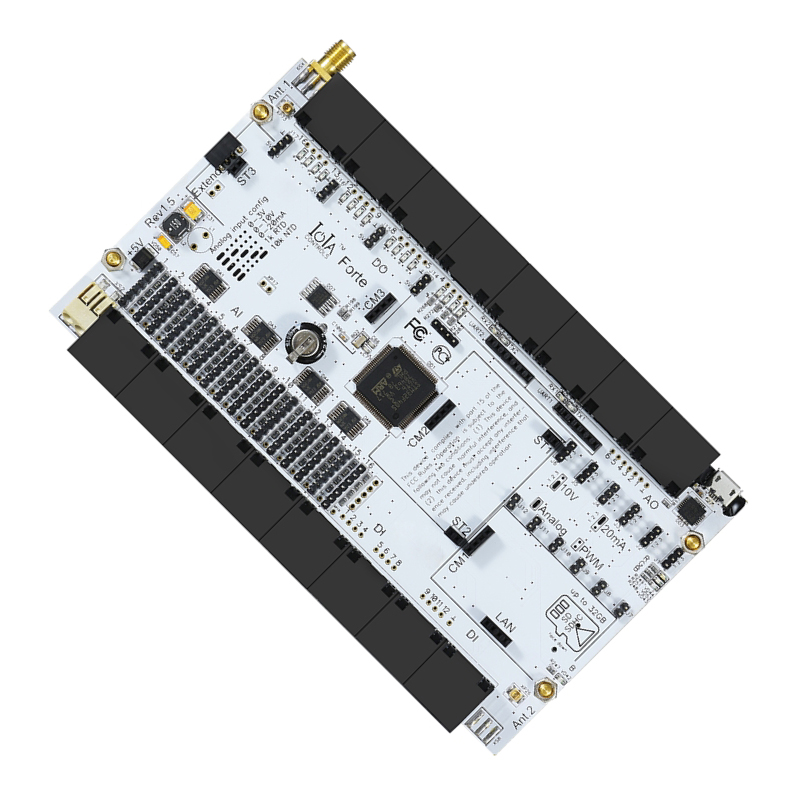

Factory For Custom Electronics Manufacturing - Custom-made High Quality White Solder Mask PCB Electronics Assembly Service For IoT device 1-32 Layer Multilayer Printed Circuit Board PCB PCBA Manufacturer – PhiliFast

Factory For Custom Electronics Manufacturing - Custom-made High Quality White Solder Mask PCB Electronics Assembly Service For IoT device 1-32 Layer Multilayer Printed Circuit Board PCB PCBA Manufacturer – PhiliFast Detail:

PRODUCT SPECIFICATION:

| Base Material: | FR4-TG140 | Surface Finish: | HASL(Lead Free) |

| PCB Thickness: | 1.6mm | Solder Mask: | White |

| PCB Size: | 62*150mm | Silkscreen: | White |

| Layer Count: | 2/L | Cu Thickness | 35um(1oz) |

| Mounting Type: | SMT+DIP | SMT Package | 0201,BGA, QFN |

| Testing Service | AOI,X-Ray,Function Test | Supplier type | Assembly factory |

Turnkey Sevices:

1. PCB fabrication

2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing

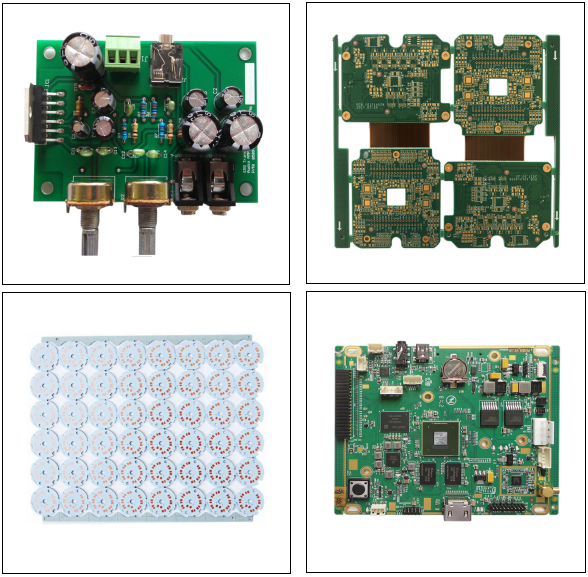

Main Product:

Our Advantage:

1, Programming and Functional test

2, IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test.

3, Professional service. ISO SMT and through hole assembly, over 10 years experience.

4, Certification: 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001

5, Warranty period for PCBA: 2 years.

PCBA PROCESSING CAPABILITY:

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole,PCB enclosure assembly |

| Lead Time | Prototype: 10-12 working days. Mass order: 18~20 working days |

| Testing on products | Flying Probe Test,E-Testing, X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order |

| Files type | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) | |

| Assembly: Pick&Place file, Assembly drawing | |

| PCB Panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) | |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 01005 size |

| BGA and QFN For Chip | |

| Double-sided SMT Assembly | |

| Fine Pitch to 0.8mils | |

| Part Removal and Replacement | |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

PCB PROCESSING CAPABILITY:

|

1 |

Layers | 1-32 Layer |

| 2 | Board material type | FR4,Ceramic substrate board,aluminum based board, high-Tg, Rogers and more |

| 3 | Compound material lamination | 4 to 6 layers |

| 4 | Maximum dimension | 600 x 1200mm |

| 5 | Board thickness coverage | 0.2 to 6.00mm |

| 6 | Minimum line width | 3mil |

| 7 | Minimum line space | 3mil |

| 8 | Outer layer copper thickness | 8.75 to 175µm |

| 9 | Inner layer copper thickness | 17.5 to 175µm |

| 10 | Drilling hole diameter (mechanical drill) | 0.25 to 6.00mm |

| 11 | Finished hole diameter (mechanical drill) | 0.20 to 6.00mm |

| 12 | Hole diameter tolerance (mechanical drill) | 0.05mm |

| 13 | Hole position tolerance (mechanical drill) | 0.075mm |

| 14 | Laser drill hole size | 0.10mm |

| 15 | Board thickness and hole diameter ratio | 10:1 |

| 16 | Solder mask type | Green, Yellow, Black, Purple, Blue, White and Red |

| 17 | Minimum solder mask | Ø0.10mm |

| 18 | Minimum size of solder mask separation ring | 0.05mm |

| 19 | Solder mask oil plug hole diameter | 0.25 to 0.60mm |

| 20 | Impedance control tolerance | ±10% |

| 21 | Surface finish | HASL(Lead Free), ENIG, immersion silver, gold plating, immersion tin and gold finger |

Fast Delivery:

PCB In 12Hours

PCBA In 3Days

Main Products Application:

*Medical Products

* Automotive Products

* Industrial Products

* Communication Products(AVL/GPS/GSM Devices)

* Consumer Electronics.

PCB Assembly Procedures:

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

PHILIFAST provides you the best PCB manufacture and assembly experience

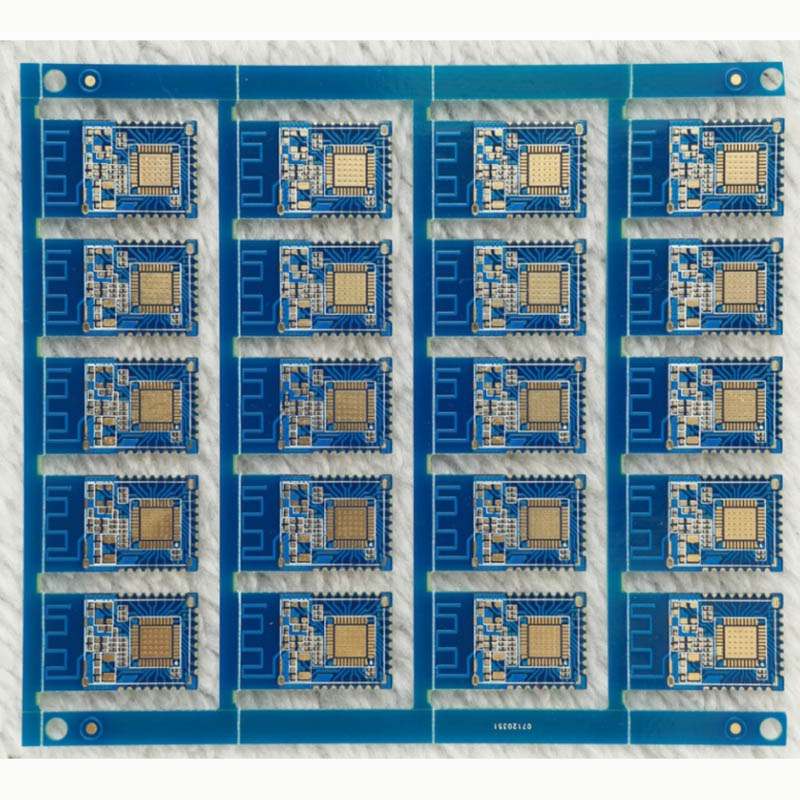

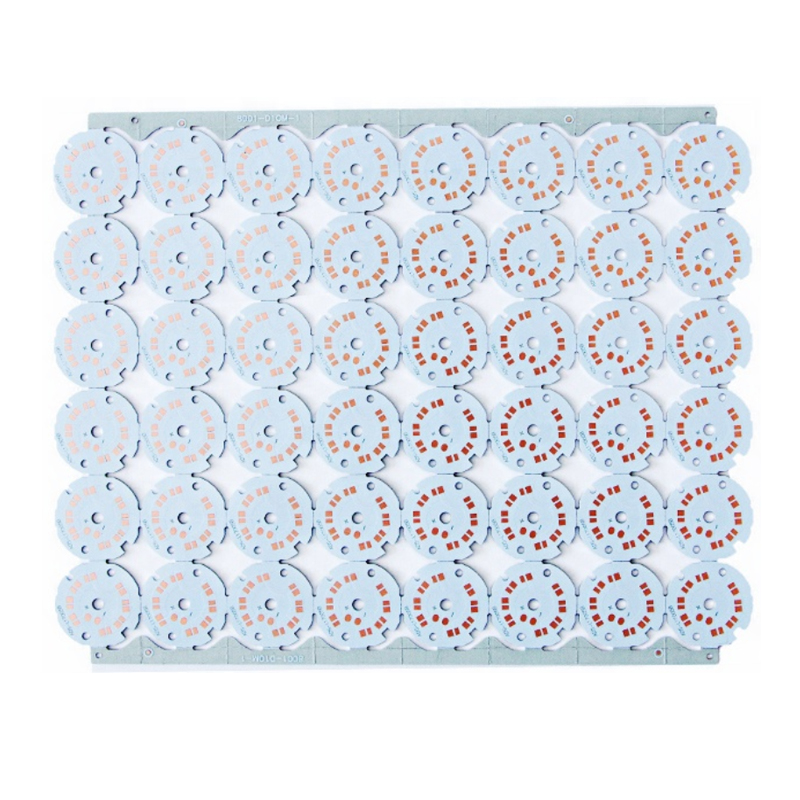

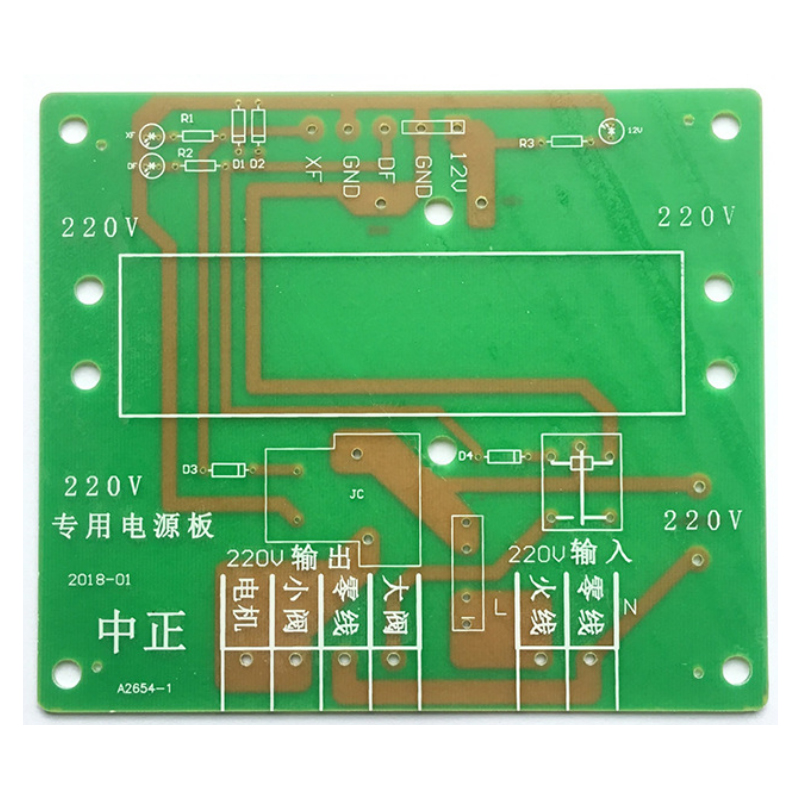

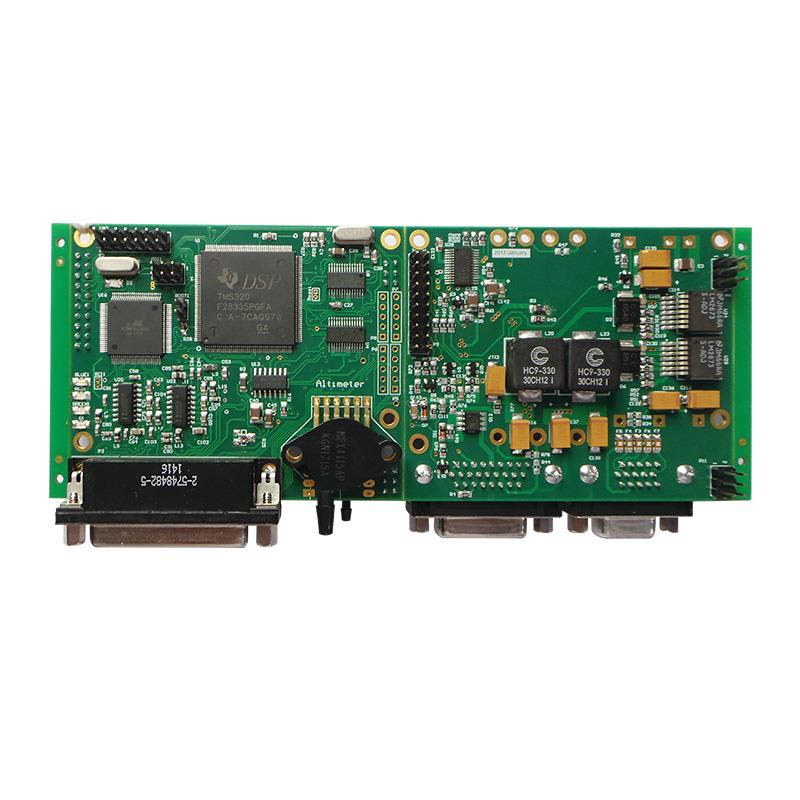

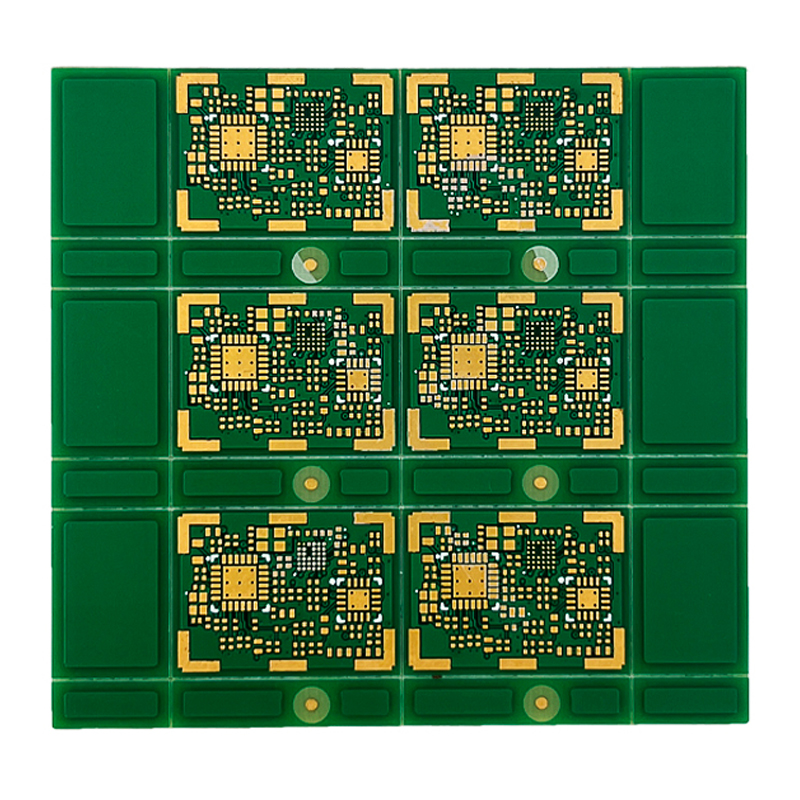

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory For Custom Electronics Manufacturing - Custom-made High Quality White Solder Mask PCB Electronics Assembly Service For IoT device 1-32 Layer Multilayer Printed Circuit Board PCB PCBA Manufacturer – PhiliFast, The product will supply to all over the world, such as: Muscat, Azerbaijan, Argentina, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!