Factory wholesale Circuit Board Layout - High Quality 4L FPC Flex PCB Board Flexible Printed Circuit Board PCB OEM Fabrication And Assembly IN CHINA FACTORY – PhiliFast

Factory wholesale Circuit Board Layout - High Quality 4L FPC Flex PCB Board Flexible Printed Circuit Board PCB OEM Fabrication And Assembly IN CHINA FACTORY – PhiliFast Detail:

PRODUCT SPECIFICATION:

| Base Material: | FR4&PI | Surface Finish: | ENIG |

| PCB Thickness: | 1.6mm | Solder Mask: | Green/ Yellow |

| PCB Size: | 90* 110mm | Silkscreen: | White |

| Layer Count: | 4/ L | Cu Thickness | 35um (1oz) |

PHILIFAST Focus on fpc OEM manufacture and assembly service for many years, you can get quick turn flexible pcb prototypes from our factory. Our professional engineer team will provide best solution to optimize your production of PCB boards.

FPC Application:

1. Camera, digital camera, DV

2. Printer, fax machine, scanner

3. Laptop, LCD screen, CD- ROM drive, hard disk, HDD

4. Recorderhead, laser bald, VCD, DVD

5 Car, car DVD, auto meter, GPS

6. Aerospace, satellite

7. Medical equipment

8. Instrumentation

9. Digital camera/CCTV camera/Drones/Home Appliance

10. Car electronics/Toy for Children

Peculiarity of FPC:

1. Small size, high density integration

2. Save space

3. Simplify layout procedure and simplify wiring.

4. Save human resourcescost

5. with good flexibility and folded easily and freely.

Main Product:

What else we can do for you:

1, PCB Production Service. (FR- 4, HI- TG, Aluminum, FPC,TEFLON, Rogers, CEM-1)

2, FPC, Rigid- Flex PCB.

3, PCB Assembly Service. (SMT, BGA, DIP)

4, IC program with HEX file.

5, PCBA Housing assembly serivce.

6, PCBA Final Functional Testing.

7, PCB & PCBA Copy Service.

8, Electronic Components Purchasing & BOM List Purchasing Services

9, PCB SMT Stencil. (Laser cut & Etching)

10, Cable assembly

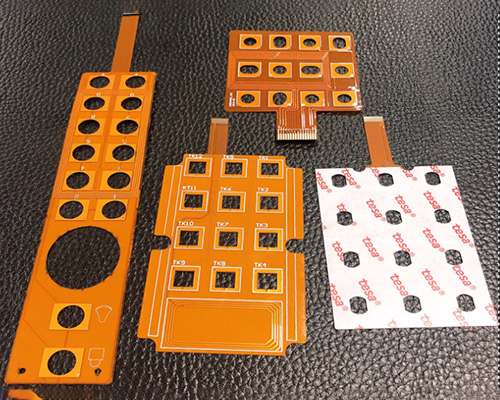

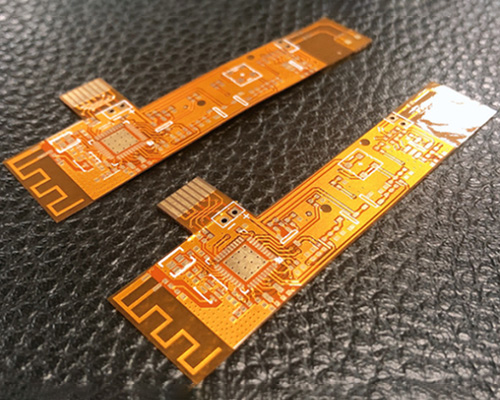

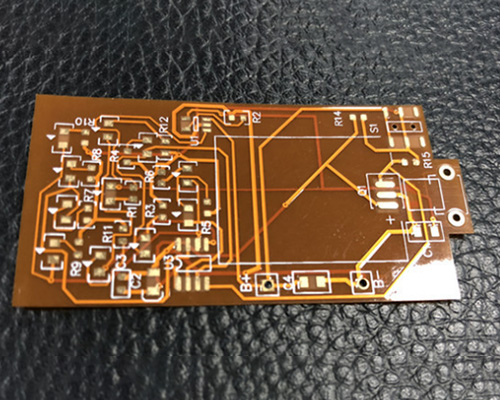

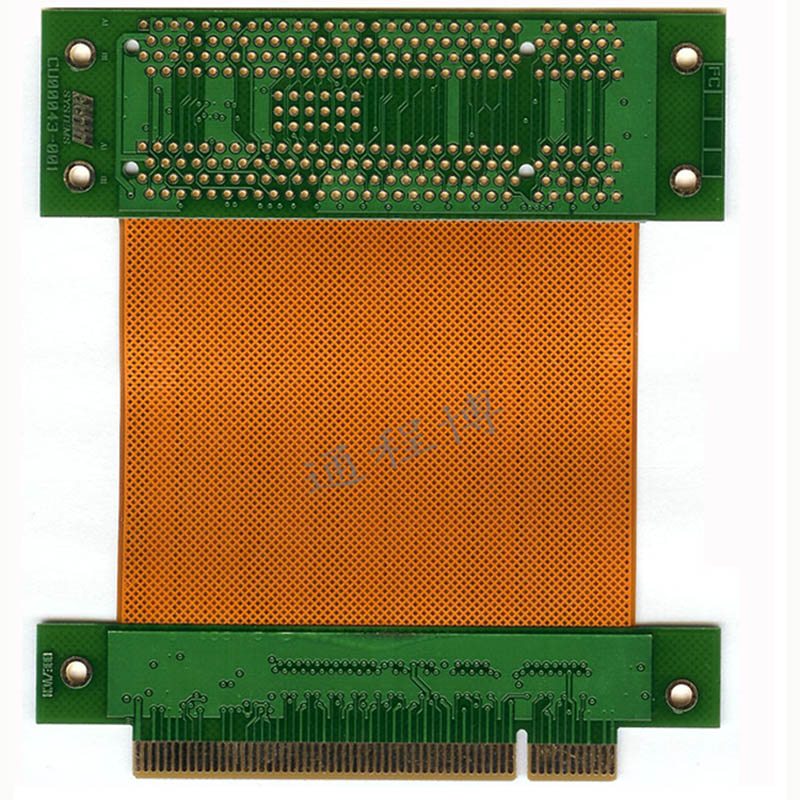

FPC&Flex-Rigid Circuit Board:

| Type of the order | Mass production | Sample production | |

| Rigid-Flex layers | 10 Layer | 10 Layer | |

| Rigid-Flex layers | Flexible Layer | 18 Layer | 20 Layer |

| Total Layer | 22 Layer | 24 Layer | |

| Min. Copper thickness of FCCL (um) | 12um | 2um | |

| Min. thickness (mm) | Double side FPC | 0.11mm | 0.11mm |

| 4 layers Rigid-flex | 0.26mm | 0.26mm | |

| Line width spacer(um) | Inner layer (Hoz) | 65/65 | 50/60 |

| Outer layer (Hoz+platting) | 75/75 | 65/75 | |

| Min. Hole size(mm) | Min Mechanical Drill | 0.1mm | 0.05mm |

| Min Laser Drill | 0.1mm | 0.075mm | |

| Impedance control | ±10% | ±8% | |

| FPC routing tolerance (mm) | ±0.1 | ±0.05 | |

| Solder Mask | Green, Yellow, White, Black… | ||

| Silk Screen | White , Black ,Yellow… | ||

| HDI | 2+C+2 | ||

| Structure | Book, Air- gap, Fly- tail, Unsymmetrical, Semi- flex | ||

| Material | Polymide(PI), PET,FR- 4, Halogen- free, Halogen(Lead free) | ||

| Heavy copper Rigid- Flex | M(2oz) | ||

We produce and assembly PCBs as per customer’s design files, we do not design pcb itself. If you have any inquiry,please send your design to us for quote.we’ll be your best EMS vendor.

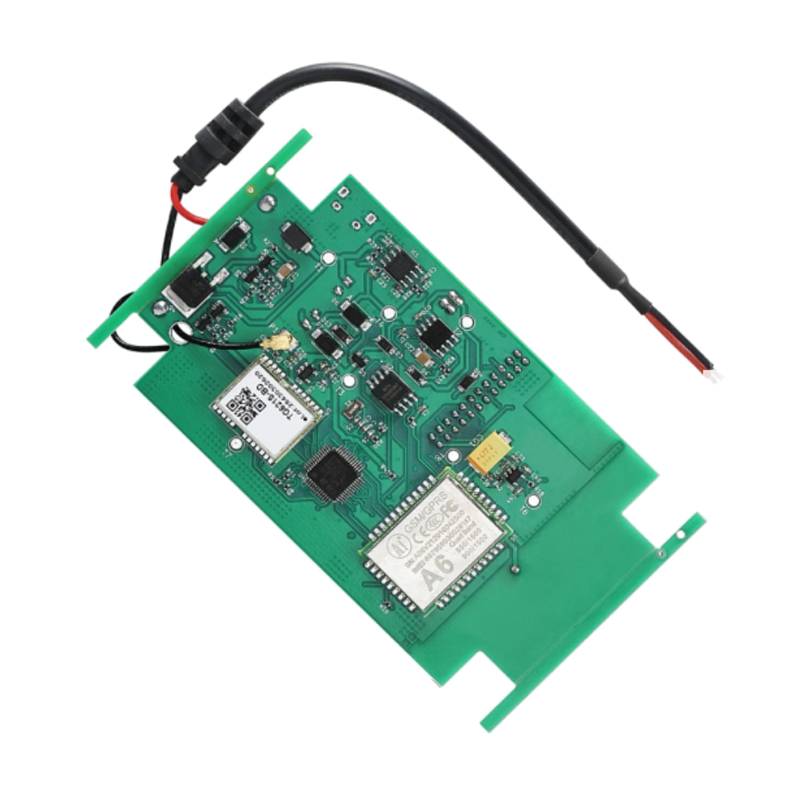

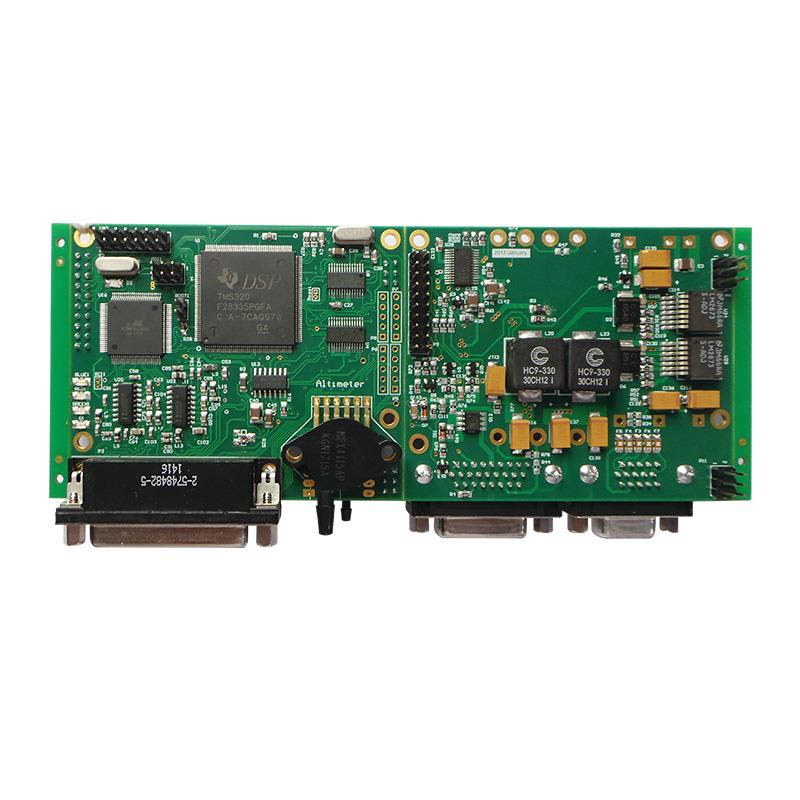

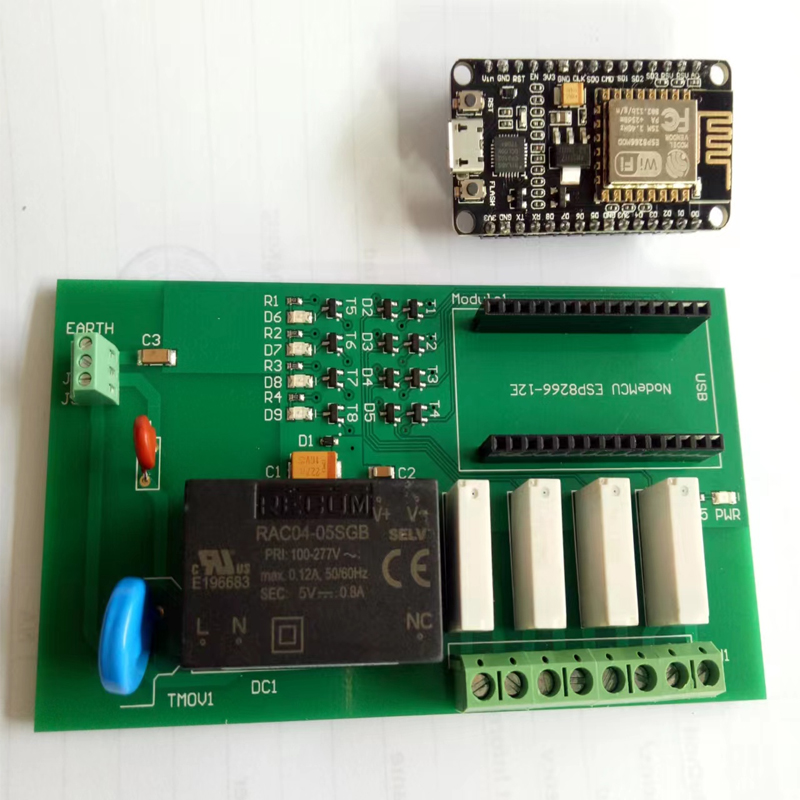

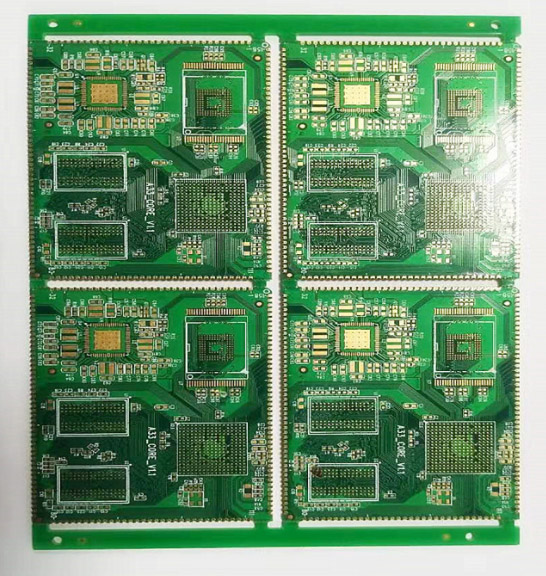

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Factory wholesale Circuit Board Layout - High Quality 4L FPC Flex PCB Board Flexible Printed Circuit Board PCB OEM Fabrication And Assembly IN CHINA FACTORY – PhiliFast, The product will supply to all over the world, such as: Macedonia, Johannesburg, Riyadh, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!