With the development of electronic technology, circuit boards, as the carrier of electronic components are inseparable with our lives, the higher demands and diversification of electronic products has become the driving force of the development of circuit board technology. There are many different kinds of printed circuit boards, I’ll introduce one kind of special type of PCB, -Rigid -Flex Printed circuit board.

The definition of the Rigid-Flex PCB:

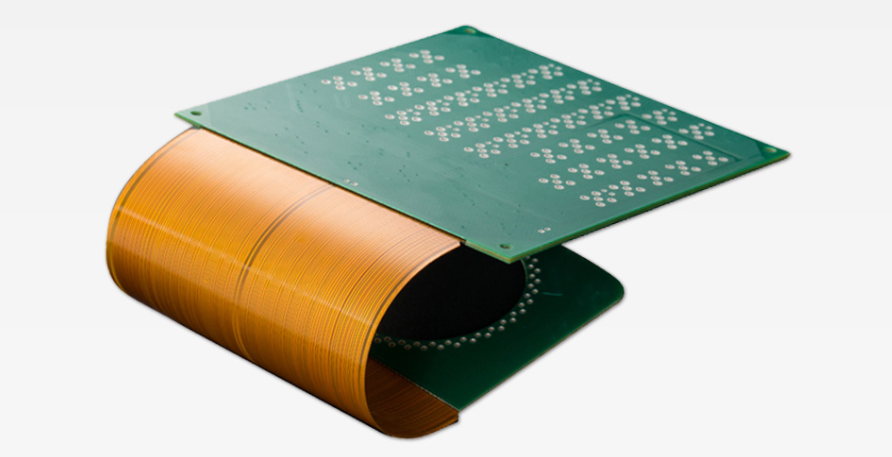

Rigid flex PCB combines the best of both rigid boards and flexible circuits integrated together into one circuit. which are hybrid constructions consisting of rigid and flexible substrates laminated together into a single structure. Rigid flex circuits have been used in the military and aerospace industries for more than 20 years. In most rigid flex circuit boards, the circuitry consists of multiple flexible circuit inner layers selectively attached together using an epoxy pre- preg bonding film, similar to a multilayer flexible circuit. However, a multilayer rigid flex circuit incorporates a board externally, internally or both as needed to accomplish the design. Rigid flex circuits provide higher component density and better quality control. Designs are rigid where extra support is needed and flexible around corners and areas requiring extra space.

The advantage of Rigid-Flex PCB:

There are many advantages of this kind of PCB:

1. Three-dimensional assembly:

Enables optimized packaging, and can be bent or folded to fit into small device enclosures.

2. Increase system reliability:

Improves reliability by eliminating separate boards, cables and connectors.

3. Reduce assembly error:

Reduces the errors common in hand wired assemblies.

4. Reduce packaging complexity:

Substantial weight& packaging size reduction is a benefit over wires and wire harnesses.

5. Better signal transfer:

Minimal geometry changes to cause impedance discontinuities.

6. Reduce assembly cost:

Cost reduction in purchasing logistics and assembling because of economisation of extra cables, connectors and soldering processes.

The main application of Rigid-Flex PCB:

1. SSD application: SAS SSD, DDR 4 SSD, PCIE SSD.

2. Machine vision application: Industrial camera ,Unmanned Aerial Vehicle .

3. Others: consume electronics, medical devices, ect....

Rigid- Flex are widely used in varies of electronics fields, further development are being expected.

PHILIFAST will provide you most professional electronics engineering manufacture& assembly service for your Rigid- flex PCB projects, for more details, just consult experts from PHILIFAST for solutions.

Post time: Jun-21-2021