Popular Design for Surface Mount Pcb Assembly - OEM PCB Enclosure Assembly Circuit Board Manufacturing and PCBA assembly factory.One-stop PCB Custom Service – PhiliFast

Popular Design for Surface Mount Pcb Assembly - OEM PCB Enclosure Assembly Circuit Board Manufacturing and PCBA assembly factory.One-stop PCB Custom Service – PhiliFast Detail:

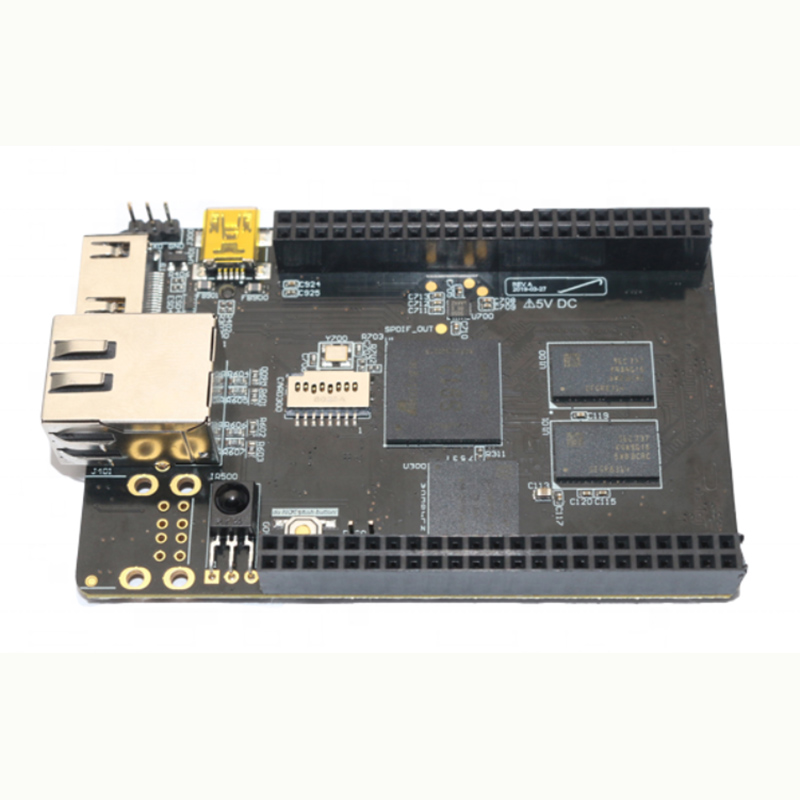

PRODUCT SPECIFICATION:

| Base Material: | FR4- TG140 | Surface Finish: | ENIG |

| PCB Thickness: | 1.6mm | Solder Mask: | Black |

| PCB Size: | 50* 126mm | Silkscreen: | White |

| Layer Count: | 4/ L | Cu Thickness | 35um (1oz) |

Technical Requirement for pcb assembly:

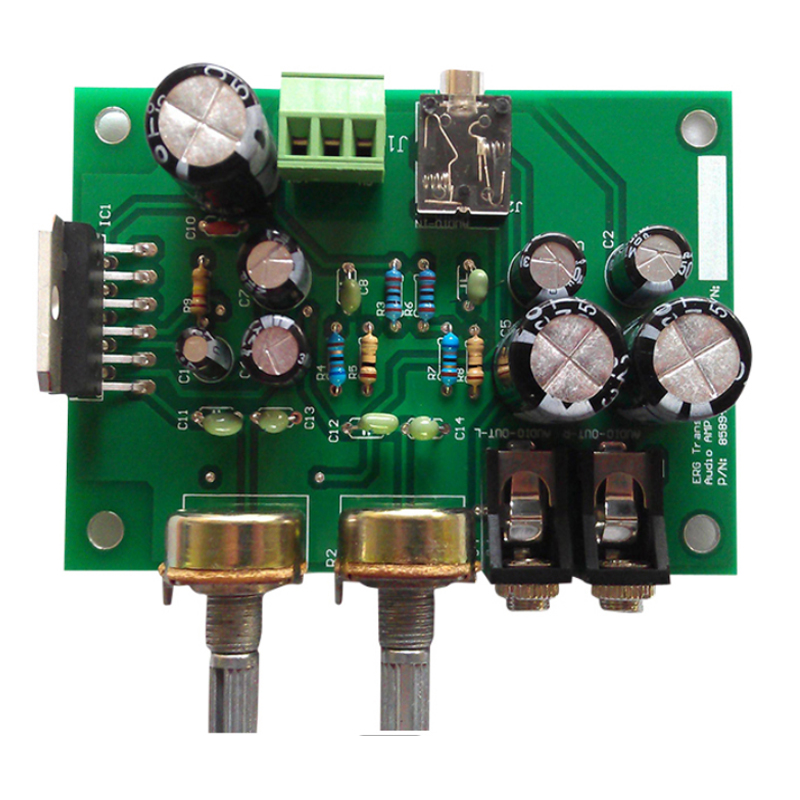

1. Professional Surface-mounting and Through- hole soldering Technology.

2. Various sizes like 1206, 0805, 0603 components SMT technology.

3. ICT (In Circuit Test), FCT (Functional Circuit Test) technology.

4. PCB Assembly With CE, FCC, Rohs Approval.

5. Nitrogen gas reflow soldering technology for SMT.

6. High Standard SMT& Solder Assembly Line.

7. High density interconnected board placement technology capacity.

Production Requirement for pcb assembly:

1. Gerber Files (Eagle and PCB File are available).

2. BOM list.

3. Clear pictures of PCBA or PCBA samples to us.

4. Pick N Place file.

5. Test procedure for PCBA.

About us:

Shenzhen Fhilifast Electronics Co., Ltd. Found in 2005. Through more than 10 years of continuous development, the company has introduced the most advanced production equipment, and established a professional engineering team, accumulated abundant experience of production and management during the production.

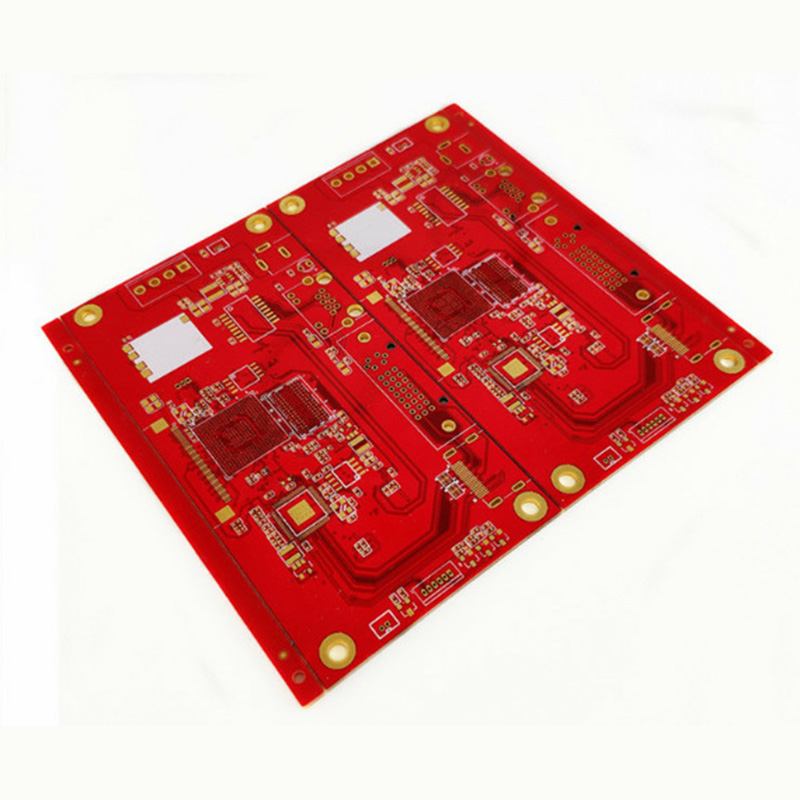

Our company has complete quality management system, a full set of supply chain system, and achieved large-scale production. Our customers market cover all over the world, the main products and technologies are exported to European and American markets. All products complyfacture and PCB assembly provider, Our Products include ordinary single- sided, double- sided and multilayer PCB, also cover Rigid- flex PCB, heavy- copper PCB, metal-base PCB, hybrid PCB, HDI, and other high- frequency boards.

• The plant area is about 7,500 square meters and the total number of employees exceeds 400.

• The monthly production capacity is as high as 10,000 square meters.

PCB Enclosure Products:

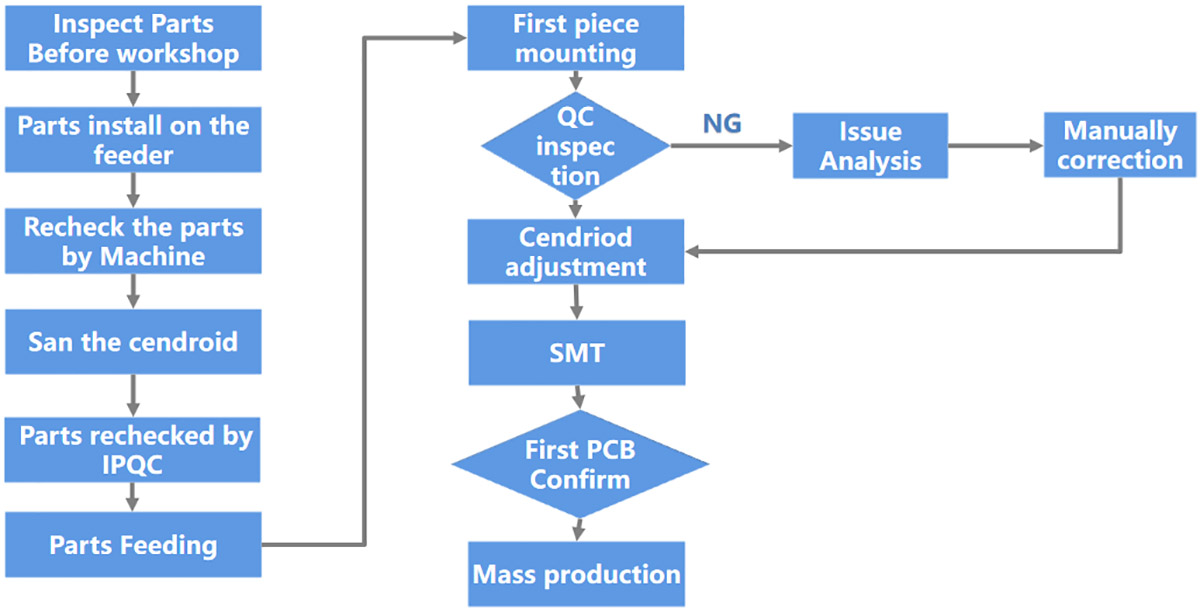

SMT Operation:

PCBA Lead Time:

| PCBA | Sample | Mass order | Urgent |

| 1-2L | 14-18days | 13-20days | 12-24hours |

| 4- 8L | 18-25days | 18-27days | 48-96hours |

| 10-18L | 22-30days | 20-32days | 120hours |

| 20-28L | 20-35days | ||

| Packaging Detail: | Vacuum package , ESD package | ||

Quality Control:

AOI Testing

Checks for solder paste

Checks for components down to 0201″

Checks for missing components, offset, incorrect parts, polarity

X-Ray Inspection

X-Ray provides high-resolution inspection of:

BGAs.

Micro BGAs.

Chip scale packages.

Bare boards.

In- Circuit Testing

In- Circuit Testing is commonly used in conjunction with AOI minimizing functional defects caused by component problems.

Power-up Test

Advanced Function Test.

Flash Device Programming.

Functional testing.

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Popular Design for Surface Mount Pcb Assembly - OEM PCB Enclosure Assembly Circuit Board Manufacturing and PCBA assembly factory.One-stop PCB Custom Service – PhiliFast, The product will supply to all over the world, such as: Frankfurt, Auckland, Birmingham, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!