Quality Inspection for Surface Mount Board - China OEM Supply PCBA Prototype Manufacturer Electronic PCB Assembly Service 4 Layer PCB Fabrication For Defense and Military Industry – PhiliFast

Quality Inspection for Surface Mount Board - China OEM Supply PCBA Prototype Manufacturer Electronic PCB Assembly Service 4 Layer PCB Fabrication For Defense and Military Industry – PhiliFast Detail:

PRODUCT SPECIFICATION:

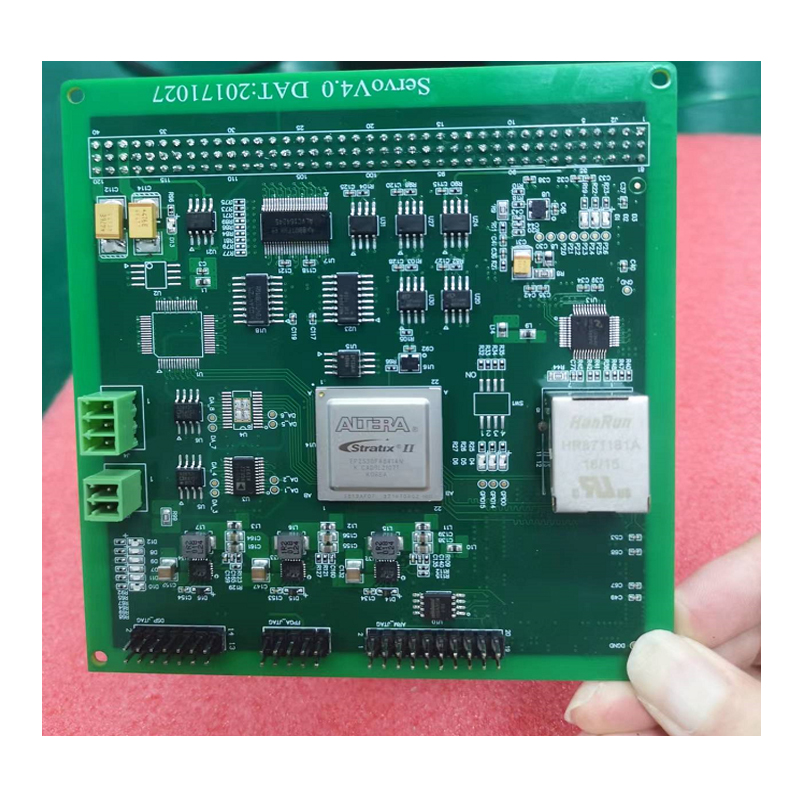

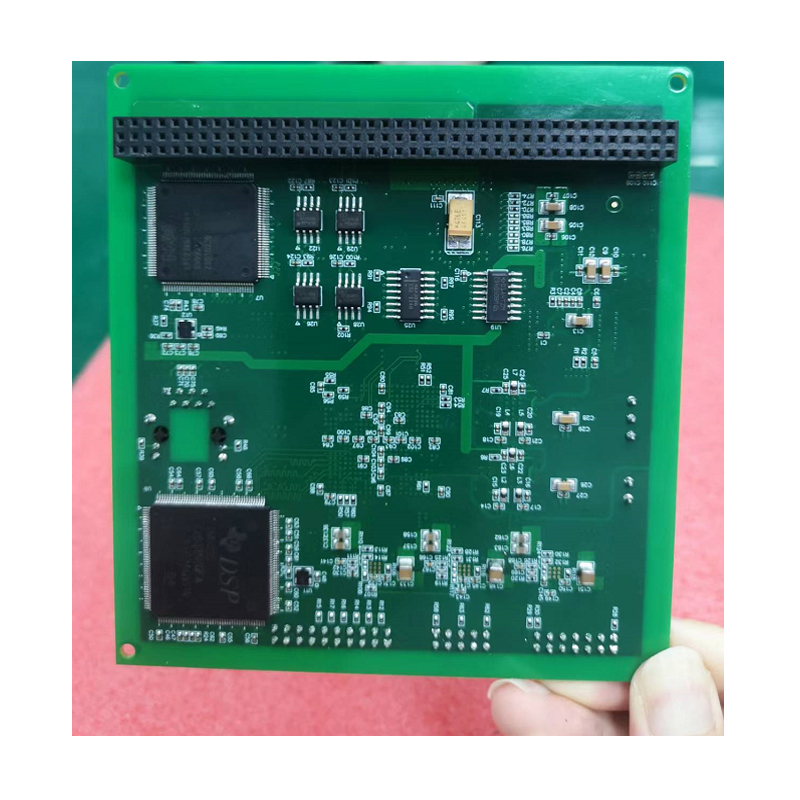

| Base Material: | FR4-TG150 | Surface Finish: | HASL(Lead Free) |

| PCB Thickness: | 2.0mm | Solder Mask: | Green |

| PCB Size: | 105*108mm | Silkscreen: | White |

| Layer Count: | 4 Layer | Cu Thickness | 35um(1oz) |

| Mounting Type: | SMT+DIP | SMT Package | BGA, QFN |

| Testing Service | AOI,X-Ray,Function Test | Supplier type | Assembly factory |

Turnkey Sevices:

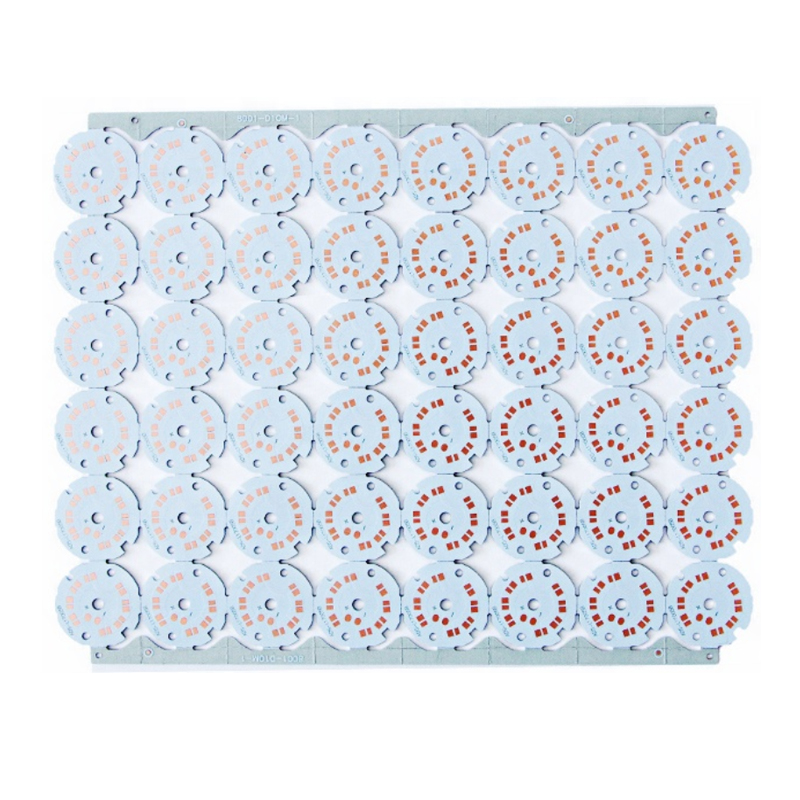

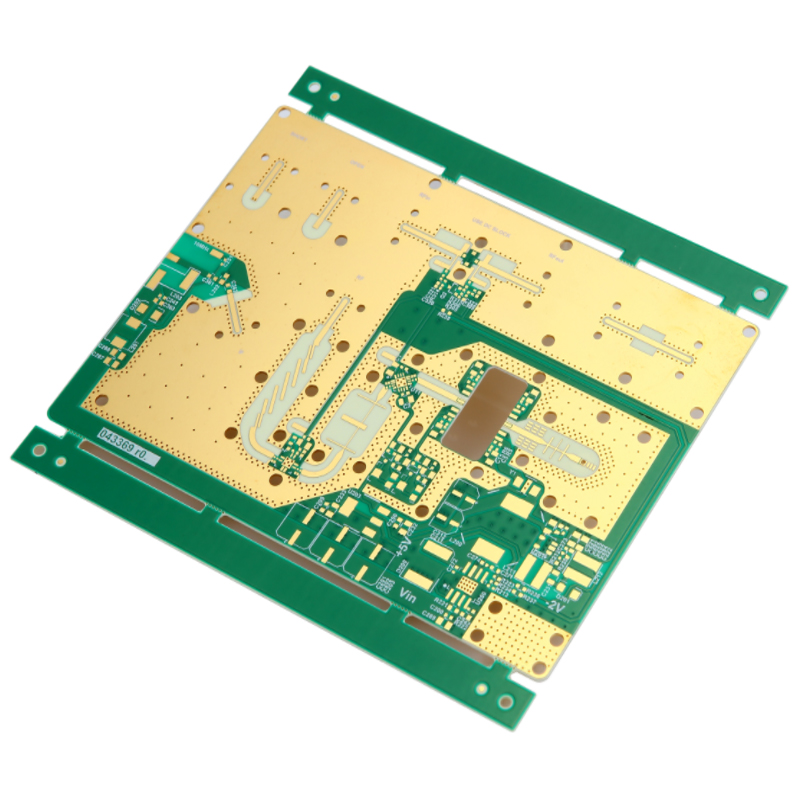

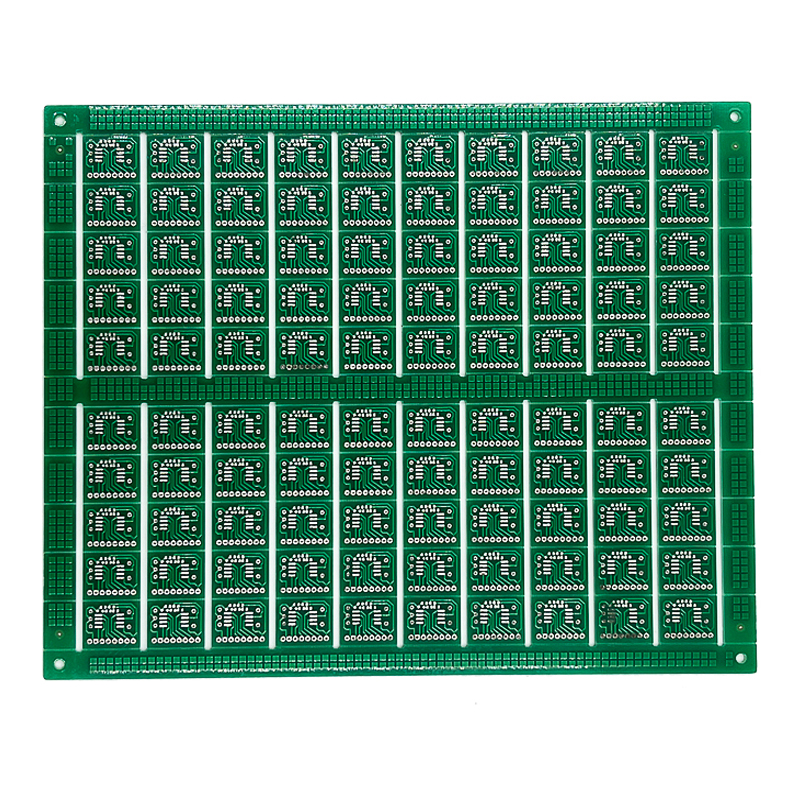

1. PCB fabrication: 1-32L PCB,HDI PCB,Aluminum-base PCB,FPC,Rogers PCBs…

2. Components supply: all resistors, compacitors, chips based on brand, connectors, and any other kinds of parts(Providing the components price details based on BOM files. all parts are speculated and used under permission.)

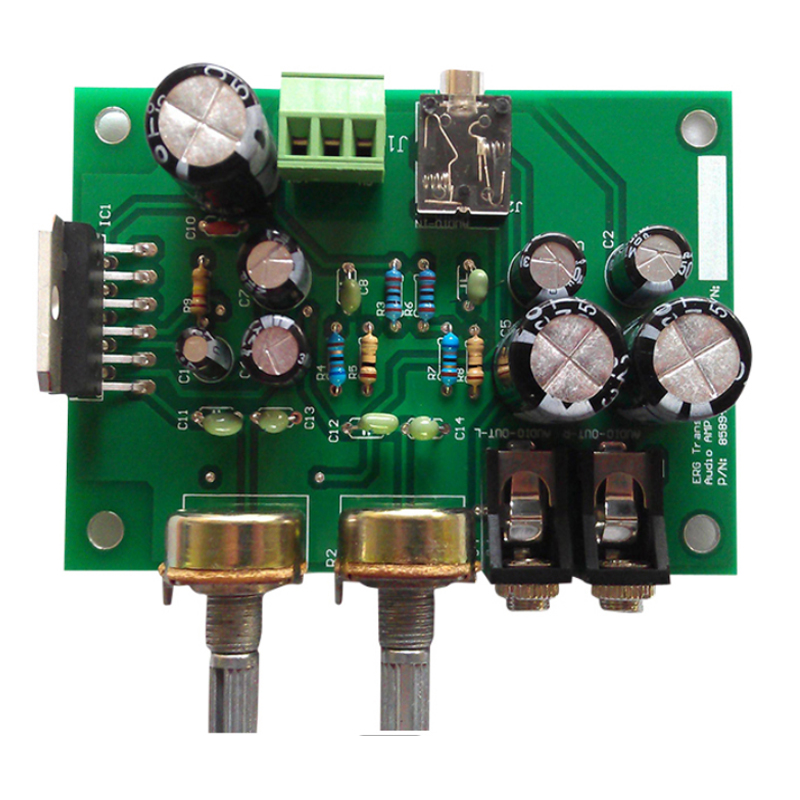

3. PCB assembly: SMT and through-hole assembly

4. IC program and Function test and finished product assembly.

Product Details:

Application

1, Consumer Electronics

2, Computer accounting, communication

3, Industrial control, automotive electronics

4, Medical equipment

5, Defense and Aerospace

PCBA PROCESSING CAPABILITY:

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole,PCB enclosure assembly |

| Lead Time | Prototype: 10-12 working days. Mass order: 18~20 working days |

| Testing on products | Flying Probe Test,E-Testing, X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order |

| Files type | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) | |

| Assembly: Pick&Place file, Assembly drawing | |

| PCB Panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) | |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 01005 size |

| BGA and QFN For Chip | |

| Double-sided SMT Assembly | |

| Fine Pitch to 0.8mils | |

| Part Removal and Replacement | |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

PCB PROCESSING CAPABILITY:

|

1 |

Layers | 1-32 Layer |

| 2 | Board material type | FR4,Ceramic substrate board,aluminum based board, high-Tg, Rogers and more |

| 3 | Compound material lamination | 4 to 6 layers |

| 4 | Maximum dimension | 600 x 1200mm |

| 5 | Board thickness coverage | 0.2 to 6.00mm |

| 6 | Minimum line width | 3mil |

| 7 | Minimum line space | 3mil |

| 8 | Outer layer copper thickness | 8.75 to 175µm |

| 9 | Inner layer copper thickness | 17.5 to 175µm |

| 10 | Drilling hole diameter (mechanical drill) | 0.25 to 6.00mm |

| 11 | Finished hole diameter (mechanical drill) | 0.20 to 6.00mm |

| 12 | Hole diameter tolerance (mechanical drill) | 0.05mm |

| 13 | Hole position tolerance (mechanical drill) | 0.075mm |

| 14 | Laser drill hole size | 0.10mm |

| 15 | Board thickness and hole diameter ratio | 10:1 |

| 16 | Solder mask type | Green, Yellow, Black, Purple, Blue, White and Red |

| 17 | Minimum solder mask | Ø0.10mm |

| 18 | Minimum size of solder mask separation ring | 0.05mm |

| 19 | Solder mask oil plug hole diameter | 0.25 to 0.60mm |

| 20 | Impedance control tolerance | ±10% |

| 21 | Surface finish | HASL(Lead Free), ENIG, immersion silver, gold plating, immersion tin and gold finger |

Fast Delivery:

PCB Prototype In 12Hours

PCBA Assembly In 3Days

PCB Assembly Procedures:

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

PHILIFAST always provides the best PCB manufacture and assembly experience

From quotation processing, engineering advice, order production, to product after-sales, our professional sales and engineering team will provide you with full service

Any question, Just send us email: sales@fljpcb.com

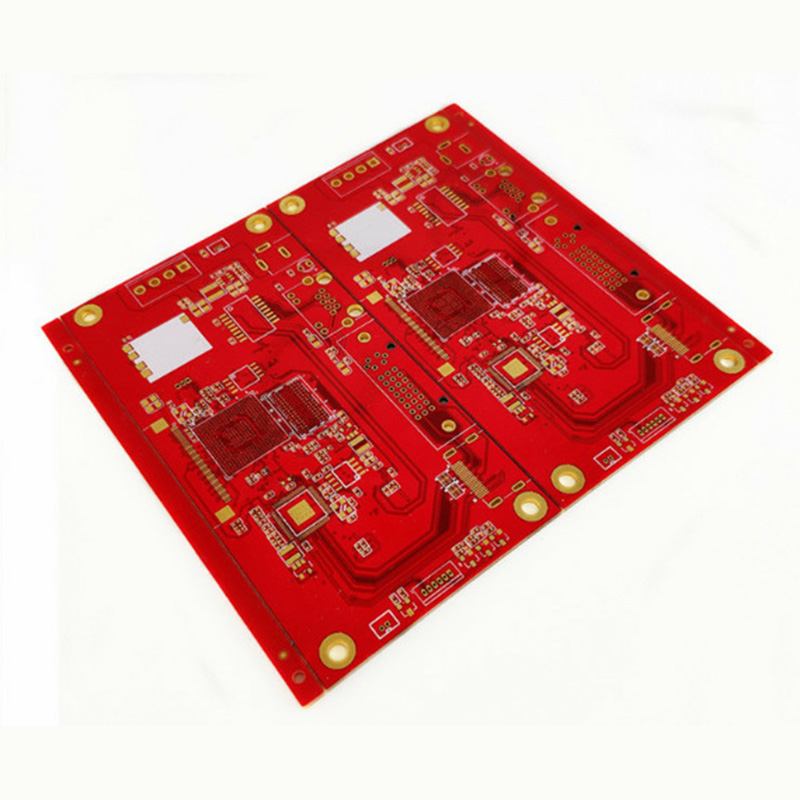

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for Quality Inspection for Surface Mount Board - China OEM Supply PCBA Prototype Manufacturer Electronic PCB Assembly Service 4 Layer PCB Fabrication For Defense and Military Industry – PhiliFast, The product will supply to all over the world, such as: Ecuador, Muscat, Netherlands, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.