Sulfuric acid copper plating plays a very important role in PCB electroplating. The quality of acid copper plating directly affects the copper layer quality on the PCB. It also affects related mechanical properties. It can affect later processing steps. So controlling the quality of acid copper plating is a key step in PCB electroplating. Many large factories find it hard to control this step well. Based on many years of work in plating and technical service, I give a short summary below. I hope this helps plating people in the PCB field.

Common problems in acid copper plating are mainly these:

- Rough plating surface.

- Copper nodules on the board surface.

- Plating pits.

- Board surface whitening or uneven color.

Below I summarize the issues and give brief analysis, solutions, and preventive measures.

Rough Plating

Rough plating often appears at board corners. Most of the time this is due to plating current that is too high. You can lower the current. Use a clamp meter to check if the current reading is abnormal.

If the whole board is rough this rarely happens. I once saw one case at a customer. Later we found the weather was cold in winter. The brightener (brightener agent) content was too low. Also, sometimes reworked boards that lost their resist layer are not cleaned well. That can cause a similar situation.

How to check and fix:

- Lower the current and watch the result.

- Check brightener concentration.

- Ensure reworked boards are cleaned well before plating.

Copper Nodules on the Board Surface

Many factors can cause copper nodules. They can come from the electroless copper step, from the whole pattern transfer process, or from the copper plating step itself.

Causes in the electroless copper step

Copper nodules caused by the electroless copper process may come from any step in that process.

- Alkali degreasing in hard water or when drill dust is heavy (especially on double-sided boards that do not get proper resin removal) and when filtration is poor. This can cause board surface roughness and also roughness inside holes. Usually this causes rough holes. Light spot-like contamination on the board surface can be removed by micro-etch.

- Micro-etch issues: the hydrogen peroxide or sulfuric acid used in micro-etch may be poor quality. Or ammonium persulfate (or sodium persulfate) may have too many impurities. I suggest at least using CP-grade chemicals. Industrial-grade chemicals often cause other failures.

- High copper content in the micro-etch bath or low ambient temperature can make copper sulfate crystals form slowly in the bath. Cloudy or polluted bath fluid also causes problems.

Activation solution problems

Activation bath problems are often due to pollution or poor maintenance. For example, the filter pump sucks in air, the bath specific gravity is low, or copper content is high. If the activation tank is used for too long (for example more than three years) particles or colloids can form. These particles can stick to the board surface or hole walls. This often appears with rough holes.

Strip or accelerator baths

If the bath is used too long and becomes cloudy this causes trouble. Many modern strippers use fluoroboric acid formulas. These can attack the glass fiber in FR-4. This raises silicate and calcium levels in the bath. A rise in copper content and dissolved tin can also cause board surface copper nodules.

Electroless copper tank itself

The tank may have too strong activity. Air agitation may bring dust. The bath may have many suspended solid particles. You can adjust process parameters, add or replace air filter cartridges, or filter the whole tank to solve the problem.

After electroless copper, do not store boards in a dilute acid bath too long. Keep that tank clean. If the bath is cloudy change it in time. If you leave the electroless-copper-coated board too long it will oxidize. Even in acid solution it can oxidize. The oxide layer is hard to remove and that can lead to surface copper nodules.

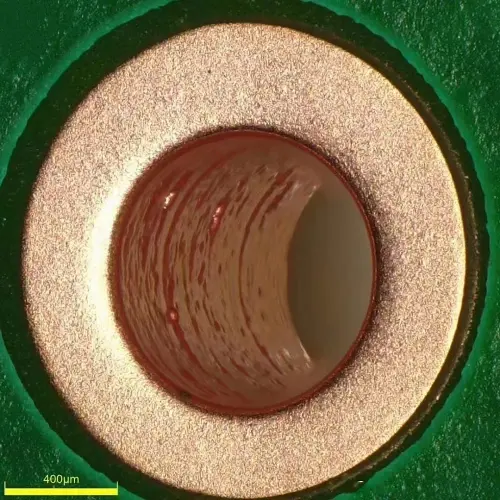

Except for surface oxidation, copper nodules from electroless copper often distribute evenly on the board. The pattern is regular. The contamination that causes them, whether conductive or not, can cause copper nodules on the final plated board. For troubleshooting, use small test boards and treat them step by step to find the cause. For a production board with this fault you can try lightly brushing with a soft brush to remove the nodules.

Pattern transfer step

Pattern transfer problems can cause nodules too. If there is residual resist after development (very thin resist film can still be plated over and then be covered) or if cleaning after development is poor, or if boards sit too long after pattern transfer, the board surface may oxidize to different degrees. This is worse when post-transfer cleaning is poor or the storage area has heavy air pollution. The solution is to improve water rinsing, organize the production schedule so boards do not wait too long, and strengthen acid degreasing.

Acid copper bath itself and causes for nodules

Normally the pre-treatment of the acid copper tank does not cause nodules because non-conductive particles mostly cause missed plating or pits. But copper tank issues that cause nodules fall into several categories: bath parameter maintenance, production operation, materials, and maintenance.

- Bath parameter maintenance: sulfuric acid content too high, copper content too low, bath temperature too low or too high. Especially in factories without proper temperature control and cooling, the current density range can fall. Under normal operation this can make copper powder form in the bath.

- Production operation: applying too high current, poor jigs or clamps, open clamp points, boards dropping into the tank and touching anodes and dissolving can all cause local high current. This makes copper powder form and drop into the bath and create nodules.

- Materials: problems with phosphor copper anodes and uneven phosphorus distribution can make trouble.

- Process maintenance: when handling big maintenance tasks, copper chips or debris can fall into the tank. Many factories do not clean anodes and anode bags well. This causes hidden risks. For big handling, clean the anode surface well and micro-etch with hydrogen peroxide to show fresh copper. Soak anode bags first in sulfuric acid + hydrogen peroxide, then in alkaline solution and wash well. Use PP filter bags with 5–10 micron gaps.

Plating Pits (Point-like Missed Plating)

Many steps can cause pits. These steps include electroless copper, pattern transfer, pre-plating treatment, copper plating, and tin plating.

- Electroless copper cause: if electroless copper baskets or racks are not cleaned well for a long time, micro-etch baths contaminated with palladium or copper can drip from the baskets onto the board surface. This creates contamination points. After copper plating these points become localized missed plating or pits.

- Pattern transfer causes: many machine and cleaning issues can cause pits. Examples are: brush machine rollers or water pickup rods contaminated with resin, dryers or air knives with oil or dust inside, poor dust removal before lamination or before screen printing, poor development in the developer, bad water wash after developing, defoamer containing silicon contaminating the board.

- Pre-plating treatment: whether for acid degreasing, micro-etch, or pre-immersion, the main agents have sulfuric acid. If water hardness is high the bath becomes cloudy and can contaminate board surface. Also poor coating of rack insulation can dissolve and spread in the tank and pollute the bath. Non-conductive micro-particles that stick to board surfaces cause missed plating of different severity.

- Acid copper tank causes: air spargers out of position cause uneven air agitation. Filter pumps may leak or the inlet may be near spargers, which brings in tiny air bubbles. These bubbles can stick to the board surface or to line edges, especially on lateral edges or line corners. Using poor quality cotton wicks or cores that are not treated well can contaminate the bath. During manufacturing cotton cores sometimes have anti-static treatments that contaminate the bath. For these problems increase aeration, and remove surface foam in time. Soak cotton cores in acid and alkaline bath to clean them before use.

Board Whitening or Uneven Color

Board whitening or uneven color can come from problems with brightener balance in the copper bath, severe organic contamination, or bath temperature too high. Acidic degreasing usually does not cause washing issues. But if the water pH is acidic and organic load is high, especially when recycle wash water is used, washing can be poor. This leads to uneven micro-etch.

Micro-etch may be low in concentration, bath copper content may be high, bath temperature may be low. These all cause uneven micro-etch. Poor rinse water quality, long rinse times, or contamination of pre-immersion acid can cause slight oxidation on the board surface. Because the copper tank is acidic and boards are energized when entering the tank, oxide is hard to remove. This gives uneven board color. If the board contacts the anode bag, uneven anode conductivity or anode passivation also cause such defects.

Brief Practical Measures and Checklist

- Keep plating current in the right range. Check with meters.

- Keep brightener and additive concentrations within spec.

- Keep bath temperature stable. Use temperature control when needed.

- Control water quality and rinse time. Do full rinses after each step.

- Maintain filtration and air filters. Replace filter cartridges when needed.

- Clean anodes and anode bags regularly. Use proper washing and soak steps.

- Use proper chemical grades (CP grade preferred). Avoid low grade industrial chemicals when purity matters.

- Avoid long storage times for boards after electroless copper. Keep tanks clean and change cloudy baths.

- Keep jigs and racks in good condition. Avoid loose clamps and open contact points.

- Prevent dust and oil from entering baths. Clean machines and air knives.

- Use test boards and step-by-step checks to locate the source of defects.

- When a defect appears, do local tests first like soft brushing, then adjust process and maintenance.