PHILIFAST, China's Leading PCB & PCBA Manufacturer

We are a professional manufacturer of PCBs and PCBA services. We handle PCB fabrication, SMT assembly, PCBA assembly and testing, component sourcing, firmware programming and flashing, and final product assembly. We focus on giving our customers fast, high-quality PCB and PCBA products.

Our PCB types cover single- and double-sided boards, fiberglass (fr4) boards, multi-layer boards (2 to 38 layers), high-end HDI boards, aluminum-core PCBs, copper-core PCBs, ceramic PCBs, high-frequency (RF) boards, flexible PCBs, and rigid-flex boards. Our products are widely used in communications equipment, medical devices, test and measurement instruments, artificial intelligence, industrial robots, renewable energy and energy storage, automotive electronics, consumer electronics, LED lighting, and industrial equipment. We are a high-tech one-stop electronics manufacturer that works to continuously improve quality, delivery time, and service for our customers.

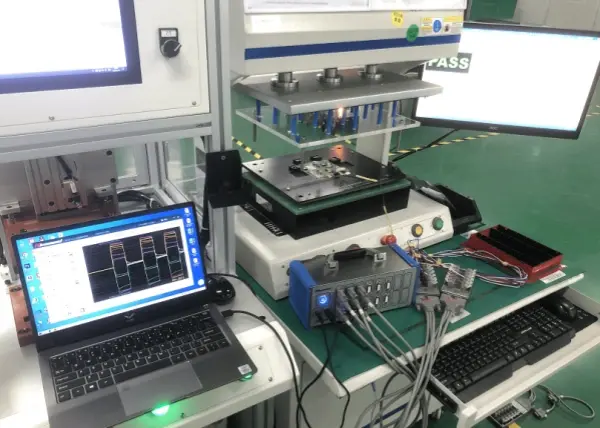

We operate 7 SMT production lines equipped with the latest Yamaha YRM20 high-speed pick-and-place machines. We also have 2 DIP/through-hole insertion lines, 2 manual soldering lines, an insertion line, wave soldering equipment, and other production tools. For inspection and testing we use advanced equipment such as X-ray, AOI (automatic optical inspection), and SPI (solder paste inspection). These tools let us offer a wide range of PCBA manufacturing services.

Whether you need large-volume production or custom small runs, we can meet your needs. We work efficiently, deliver quickly, and meet delivery schedules.

We always put quality first. We hold certifications including UL, ISO 9001, ISO 14001, and ISO 13485. We follow strict system procedures for production and control. We provide customers with high-quality products, competitive prices, fast lead times, and reliable on-time delivery.

Quality Control Process

We follow a clear quality process from Gerber review to final testing. From fabrication and component inspection to SMT/DIP assembly, IC programming and PCBA testing, every step is checked to ensure reliable boards and on-time delivery.

PCB fabrication

We analyze Gerber files before production. Check hole spacing and board strength to avoid bending or breakage. Check routing for high-frequency issues and impedance. Make sure the board design meets mounting and electrical needs.