PCB usluge

Full Lifecycle Support from Pre-Sales to After-Sales

ABOUT US Services

We provide end-to-end PCB services spanning feasibility assessment, design validation, prototyping, manufacturing, assembly, testing, remote diagnostics, repair and lifecycle management. Our goal is to reduce development risk, speed validation cycles, lower field failures, and keep products reliable throughout their lifecycle. Below is a detailed breakdown of services, deliverables and support options.

Deliverables:

Pre-production report with prioritized recommendations.

Optimized BOM suggestions and cost options.

Prototype plan and suggested test plan.

Pre-Sales Engineering & Technical Consultation

Before any production runs, we help validate the design and recommend optimizations that save cost and improve manufacturability and reliability.

Services:

Technical feasibility review: stackup, material choice, layer count, copper weight, surface finish trade-offs.

Manufacturability analysis (DFM/DFA): identify issues that cause poor yields or assembly rework.

Thermal and signal integrity review: heat dissipation strategy, thermal vias, impedance control, controlled impedance checks for high-speed traces.

Cost/volume optimization: propose alternative processes or materials to meet price/performance targets.

Documentation checklist: advise on required deliverables (Gerber, ODB++, BOM, pick-and-place, test vectors).

Confidential handling: NDA, secure file transfer and restricted access for sensitive IP.

Product Support & Specialized Services

Warranty, RMA & Lifecycle Support

Services

- RMA handling: inspection, grading, repair/replacement recommendations and disposition.

- Root cause analysis and corrective actions to prevent recurrence.

- Obsolescence monitoring: proactively identify EOL risks and propose alternates.

- Spare parts management: kitting, consignment stock and reorder planning.

Deliverables

- RMA reports, failure logs, corrective action plans, and updated BOM with recommended alternatives.

Add-On Services & Special Processes

We can support advanced needs and custom requests.

Examples:

- Controlled impedance and RF layout tuning.

- Thermal management: heatsink integration, thermal vias, metal core PCBs, and thermal interface material recommendations.

- Potting, encapsulation and conformal coating for harsh environments.

- High-voltage PCB handling and safety layout review.

- Cleanroom assembly or specialized handling for medical/space applications (on request).

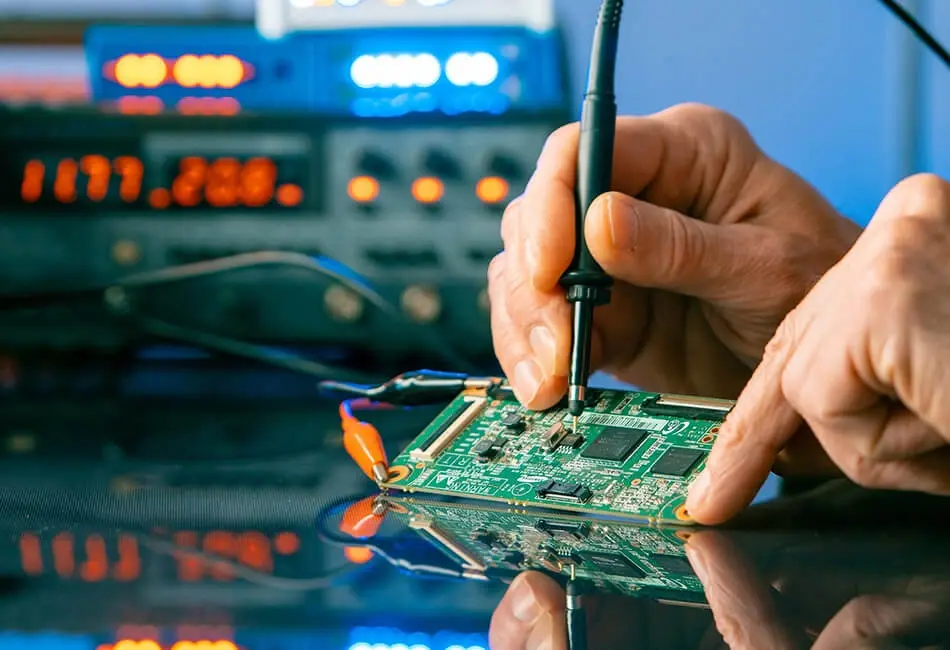

Repair, Rework & Field Service

Board-level expertise to restore function and improve long-term reliability.

Services:

- Component-level repair and rework (SMT, BGA reballing, fine-pitch, QFN).

- Pad and trace repair, copper restoration and solder mask touch-up.

- Conformal coating removal and controlled recoating.

- On-site troubleshooting and emergency repair for critical systems.

- Controlled reflow profiles and ESD/ESD-safe workstations.

Deliverables:

- Repair reports, replaced component lists, and verification test results.

Remote Support & Diagnostics

Fast troubleshooting without immediate shipping saves time and cost.

Remote capabilities

- Live guidance for test procedures and fault isolation.

- Remote firmware flashing, bootloader support and configuration guidance.

- Review of logged data, oscilloscope captures, and customer test measurements.

- Secure remote sessions (VPN/encrypted channels) for deep diagnostics.

When remote help is insufficient, we coordinate physical returns or on-site dispatch.

What Our Happy Guests are Saying

Reliable processes and secure handling of intellectual property are core to our service.

Quality Assurance & Data Security

- Standardized inspection checkpoints, process audits and supplier qualification.

- Documented change control and traceable lot records.

- Secure file transfer, access control, and NDA safeguards for customer IP.

- Continuous improvement based on failure data and customer feedback.

Typical Deliverables You Will Receive

- Fabrication files (Gerber/ODB++/IPC-2581), drill files and fabrication notes.

- BOM with manufacturer and distributor references and alternates.

- Pick-and-place files, assembly drawings and reflow profiles.

- Test plans, inspection reports, and final QA certificate.

- RMA/repair reports and root cause analysis documents.

Call to Action

Tell us about your project — upload design files or contact our team for a consult. We’ll assess feasibility, suggest optimizations and prepare a practical plan from prototype to production and long-term support.