RF PCB is a type of printed circuit board (PCB) made for carrying and handling radio frequency signals. These signals are high frequency. They usually have frequency equal to or above 300 kHz and up to 300 GHz.

Radio frequency, or RF, is a name for a group of electromagnetic waves. People use this name when the waves can work for radio communication. The range of frequency for RF is not always the same in different books. Some books say RF is from 30 MHz to 3 GHz. Some say it is from 300 MHz to 40 GHz. These ranges can overlap with the range called microwave. Some other books use a different way to split the spectrum. They say waves with wavelength from 1 megameter to 1 meter are in a group. That gives frequencies from 30 Hz to 300 MHz. The line between RF and microwave is not very clear. The line can change as parts and design methods get better.

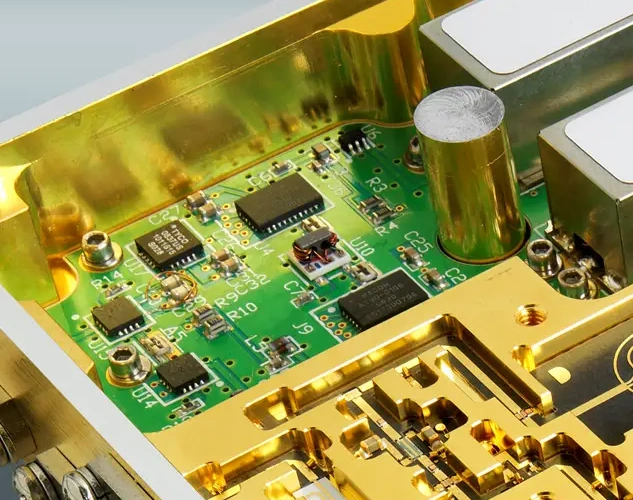

RF PCB and its main features

When we design a PCB for RF use, we must think about how transmission lines behave. For a wire or trace on a PCB, we can model it in two ways. One is the lumped element model. The other is the distributed parameter model. A common rule is this. If the geometric length l divided by the wavelength λ is equal to or larger than 0.05, then we use the distributed model. In this note, an RF link means a circuit where the transmission line needs the distributed model. In practice, PCB trace length is rarely longer than 50 cm. So we can start from analog signals at 30 MHz. Signals above 3 GHz are often called microwave. For production limits where element spacing can be 0.5 mm, people sometimes set the top frequency to 30 GHz. But that is not always useful.

From these points, we can say an RF PCB is a PCB for analog signals with frequency about 30 MHz to 6 GHz. The choice between lumped or distributed model should follow the formula above and the working frequency.

Because the substrate dielectric constant is usually high, waves move slower in the board than in air. That makes wavelength shorter on the board. For microstrip and other lines, the substrate must have low dielectric loss. The dielectric constant should not change much over the needed frequency and temperature range. The substrate should have good thermal conductivity and a smooth surface. It must stick well to the conductor.

For the metal on the trace we need high conductivity. The metal should have a small temperature coefficient of resistance. It should stick to the substrate well. It should be easy to solder.

Principles for choosing RF board material

Role of substrate in microwave PCBs

A microwave frequency PCB is not only a support for components. It is also a medium for microwave electromagnetic fields. So for RF circuits the best choice is high frequency or microwave grade substrate.

Trace impedance control

On an RF PCB the printed traces must follow normal rules like current capacity. In addition, we must control the trace characteristic impedance. The traces must be matched in impedance. So the PCB process must control trace impedance. The characteristic impedance of a trace depends on the PCB material and its physical parameters. So PCB designers must know the material performance.

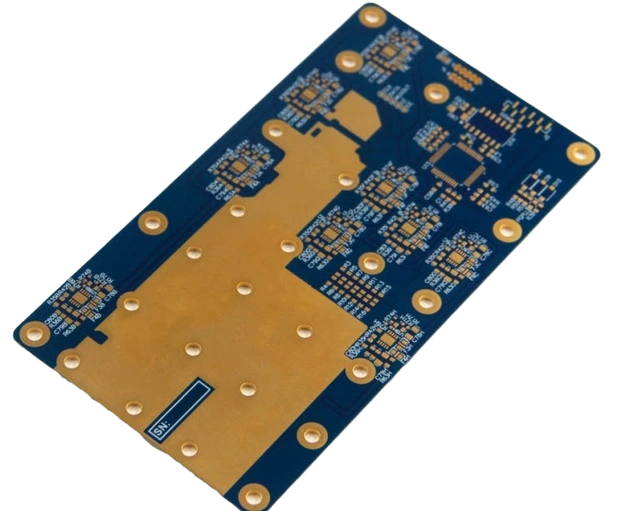

Material requirements for RF boards

RF boards usually need high frequency and high performance. People pick substrate with accurate dielectric constant. The substrate should be stable and have low loss. Also the material must work with production. For example, it must handle high temperature reflow soldering. Our company often uses fr4, TACONIC, and materials from ROGERS for RF base material.

FR-4 characteristics

fr4 (flame retardant copper clad epoxy glass fabric) has dielectric constant Er tested at 1 GHz as Er = 4.3 ± 0.2. The glass transition temperature Tg is 135 °C. For common boards we use two kinds of plate. One is standard board material. This is low cost and has mature process. The other is UV board, often called yellow board. It has UV-BLOCKING to block ultraviolet. We use it for outer layers. Its performance is a little better than the standard plate.

TACONIC material

TACONIC is a well known brand. It has many specs. Its price is higher than fr4.

ROGERS material

ROGERS material has high dielectric constant accuracy. It is stable with temperature and has low loss. We use it for high power circuits. The PCB make and process is similar to fr4 so cost of making is low. But the copper foil adhesion is low.

Substrate table

| Material type | Typical material | Dk (10 GHz) | Df (10 GHz) | Features and use |

|---|---|---|---|---|

| Fluoropolymer substrate | PTFE (polytetrafluoroethylene) | 2.1–2.3 | 0.0005–0.001 | Very low loss. Good for mmWave. Use for 5G base stations and radar. |

| Ceramic filled substrate | Rogers RO4000 series | 3.38–4.5 | 0.0027–0.004 | Mid cost. Good for microwave. Use for WiFi and Bluetooth modules. |

| Glass fiber substrate | High frequency fr4 (like Isola FR408) | 3.9–4.2 | 0.008–0.01 | Low cost. Good for mid and low RF. Use for walkie talkies and similar. |

RF issues in PCB design and solutions

In general, for circuits with frequency below microwave (this includes low frequency and low speed digital), careful layout is the first key to success. If you know the rules, you can make a good design. For microstrip and high speed digital circuits at PCB level, two or three PCB versions may be needed to ensure circuit quality. For RF circuits with frequency above microwave, you will need more versions to improve performance. So you will face many challenges during RF circuit design.

Below we list common problems and solutions.

Common problems in RF circuit design

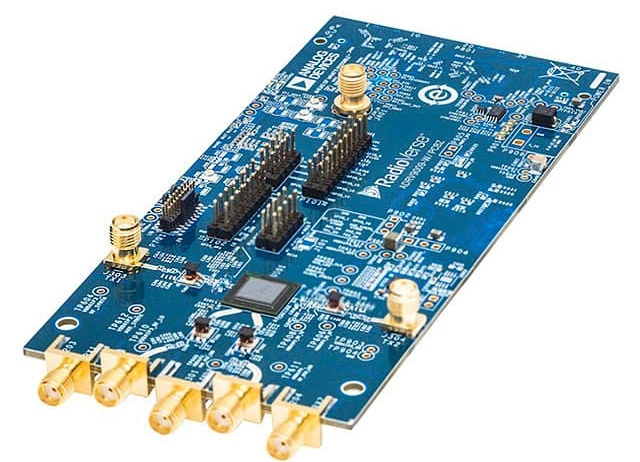

Interference between digital and analog modules

When analog RF parts and digital parts work alone, each can work well. But when they mix on the same board and share power, the whole system may become unstable. Digital signals swing between ground and Vcc by more than 3 V. The period can be short, in the nanosecond range. Because the amplitude is large and the switching is fast, digital signals include high frequency components that do not depend on the switching clock. In the analog part, from a tuned radio loop to a receiver, the voltage can be less than 1 μV. The difference between the small RF signal and digital noise can be more than 120 dB. If digital signals are not kept away from RF, the weak RF signal can get damaged. The radio may stop working or work badly.Power supply noise interference

RF circuits are sensitive to noise. They are sensitive to spikes and other high frequency harmonics. A microcontroller will suddenly draw lots of current at each internal clock cycle. Most modern microcontrollers use CMOS. If a microcontroller runs with 1 MHz internal clock, it will draw current at that rate. If we do not have good power decoupling, we will get voltage noise on the power lines. If voltage spikes get to the RF power pins, the RF block may fail.Bad ground design

If the ground is not well designed for RF, strange results can happen. In digital design, most circuits still work even if ground is not perfect. But in RF, even short ground wires act like inductors. For example, 1 nH of inductance is close to 1 mm in length. From that we can guess that a 10 mm long PCB trace has reactance about 27 ohms. If we have no good ground, many ground traces will be long and the circuit will not keep its designed characteristics.Antenna radiation interfering with other analog circuits

In PCB layout, there are other analog parts. Many boards have ADCs or DACs. A strong RF signal from a transmitter can reach the ADC input. Any trace can act like an antenna. If the ADC input does not have good handling, the RF can go into its ESD diode and cause ADC offset or errors.

RF circuit design principles and solutions

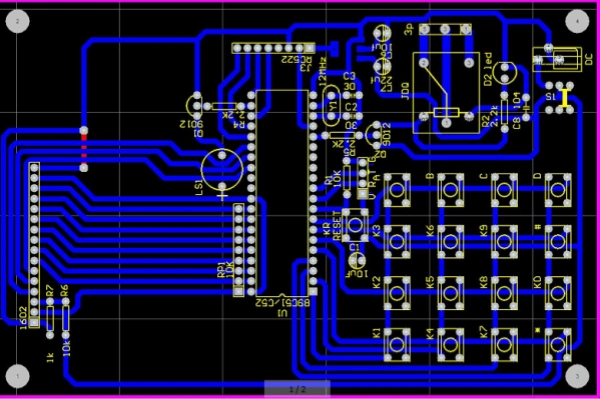

1. Definition of RF layout

When you design RF layout, follow these rules.

Keep high power amplifiers (HPAs) and low noise amplifiers (LNAs) as far apart as you can. Put high power transmit parts far from low power receive parts.

In high frequency areas on the PCB, have at least one full ground plane below and avoid vias in it. The larger the copper area the better.

Circuit and power decoupling are equally important.

Place RF outputs away from RF inputs.

Put sensitive analog signals far from high speed digital and RF signals.

2. Physical partition and electrical partition design rules

Partition means splitting the board by function. You can do physical partition and electrical partition. Physical partition deals with part layout, direction, and shields. Electrical partition deals with power distribution, RF routing, sensitive parts, signals, and ground zones.

a. Physical partition principles

Parts layout is key for good RF design. A good method is to place parts along the RF path first. Then set their direction. Place inputs away from outputs. Keep high power and low power parts apart. This helps to shorten RF paths.

b. PCB stackup design principle

A good stackup puts the main ground plane on the layer below the trace layer. Put RF traces on the plane layer. Make vias on RF paths small. This reduces path inductance and reduces cold solder joints on the main ground. Also less RF energy will leak into other layers.

c. RF parts and RF trace principles

In the board space, linear circuits like multistage amplifiers can separate RF zones. But duplexers, mixers, and IF amplifiers often make many RF and IF signals appear near each other. You should take care to lower this coupling. Route RF and IF traces carefully and leave ground space between them. The right RF path is vital for PCB performance. That is why part layout takes most of the time in phone PCB design.

d. Electrical partition principle

Most power in phone circuits is low DC so you do not need special wide traces. But for power to high power amplifiers you must make wide traces for high current. This keeps voltage drop small. Use many vias to move current from one plane to another to avoid current loss.

Power decoupling for power parts is important. If you fail to decouple the power at a high power amplifier pin, many problems can happen. High power noise can radiate across the board. Ground for high power amplifiers is very important. Designers often need a metal shield can.

e. RF input/output isolation principle

It is very important to keep RF output away from RF input. This applies to amplifiers, buffers, and filters. In worst case, if amplifier or buffer output comes back to its input with the right phase and amplitude, the part can go into self-oscillation. In good case, the circuit will be stable at all temperatures and voltages. In bad case, it will add noise and intermodulation to the RF signal.

Summary

In short, RF circuits work with distributed parameter lines. They show skin effect and coupling. This makes them different from low frequency and DC circuits. So in RF PCB design you must focus on the points above. If you do, the design will be effective and accurate.

Keep traces short when possible. Short traces reduce loss and unwanted reactance.

Use the right substrate for the needed frequency. fr4 is okay for many cases. Use Rogers or PTFE for low loss in high frequency.

Control impedance of traces. Use the right width and spacing and stackup. Measure or calculate with tools.

Keep digital and RF parts separate. Give each section its own ground return. Use decoupling at power pins close to the part.

Use ground planes and small vias for RF return. This lowers inductance.

Place filters and shielding near sensitive parts. This lowers unwanted pick up.

Test with prototypes. RF usually needs multiple rounds of layout and tune. Small changes can make big effects at high frequency.

For antennas, give a clear area and keep metal and other traces away. Antenna matching and tuning often need board space and test.

When you make high power traces, make them wide and use many vias to carry current between layers.

Basic formulas and rules to check

Use l/λ ≥ 0.05 to see if a trace needs a distributed model. l is geometric length. λ is working wavelength in the medium.

For quick inductance sense, 1 nH is about 1 mm of trace. Use this to check if long grounds add inductance.

For impedance control, know the stackup, trace width, dielectric constant, and distance to plane. Use a field solver or impedance calculator to get accurate values.

Frequently Asked Questions

An RF (radio-frequency) PCB is designed to carry RF and microwave signals (hundreds of MHz up to many GHz). It uses controlled materials, stackups and layout rules to minimize loss and preserve signal integrity.

Common choices are PTFE-based laminates and engineered materials (Rogers, Taconic, etc.) for low loss and stable dielectric properties; in some lower-frequency or cost-sensitive designs, high-grade FR-4 variants may be used.

Standard FR-4 has higher dielectric loss and less stable Dk at GHz frequencies, which increases attenuation and impedance variability—so for precision RF work PTFE/Rogers-class laminates are usually preferred.

Yes—via stubs act like short unterminated transmission lines and cause reflections. Common mitigations include back-drilling, buried/stacked vias, and careful via placement.

Common tests: VNA S-parameter (insertion/return loss), TDR/impedance checks, and thermal/aging tests to verify Dk stability and dimensional behavior.

Supply Gerbers/ODB++, target impedance values, exact layer stackup, dielectric choices (or Dk/Df targets), BGA/pitch info, via requirements (backdrill/via-in-pad), and any special routing or assembly notes. Early DFM review speeds up production and reduces risk.