Overview

Electronic products place higher demands on printed circuit boards. Parts on the board grow rapidly in number. The part sizes get smaller. Half-hole PCBs are used more and more because they are easy to solder, take little module area, and support many functions.

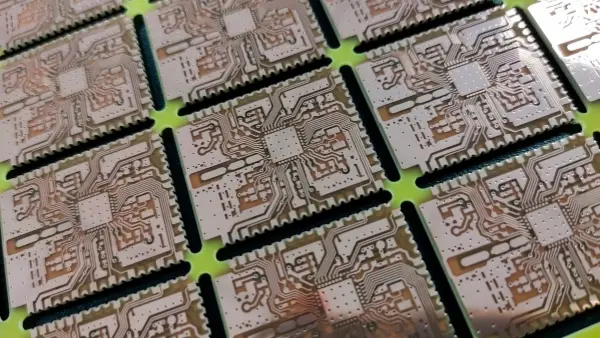

What is a half-hole PCB

A metal half-hole (or half-slot) is made by first drilling and metallizing a hole, then drilling or routing again to cut the hole in half. Simply put, it is a metallized hole at the board edge cut in half. The edge half-metallized hole process is mature. In the PCB industry this is also called a “postage-stamp hole.” You can solder the hole edge directly to the main board. This saves connectors and space. You often see it in signal circuits. Most module PCBs use half-holes.

Characteristics of metallized half-hole PCBs

The single unit is small.

The unit edge has a row of metallized half-holes. This unit is a subboard of a parent board. The metallized half-holes solder to the parent board and to component leads.

Advantages of the half-hole process

Increase pad strength. The half-hole design strengthens the edge pad mechanically. In modular PCBs it improves solder reliability. It fits high-density and high-vibration uses.

Optimize space layout. Half-holes let you place parts more flexibly and use less space. For example, in a Wi-Fi module you can solder the edge half-hole directly to the main board and cut product thickness by about 60%. This suits thin devices.

Simplify production. The process needs extra steps early on (for example, copper plating and precise singulation), but overall it is more efficient than using traditional connectors. It also avoids buying connectors.

Improve appearance. Edge half-holes make the PCB look cleaner. This meets modern product appearance needs.

Enhance signal performance. In high-frequency cases (for example 5G) half-holes can lower parasitic capacitance and cut signal loss. This raises transmission efficiency.

Processing difficulties

After forming, metallized half-hole PCBs often show problems in the hole wall copper. These include copper lift, dark copper, leftover burrs, and offset. These issues are a common challenge for PCB makers in the forming step.

A full row of postage-stamp-like half-holes is especially hard. The hole size is about 0.6 mm. The hole-wall gap is about 0.45 mm. The outer layer pattern spacing is about 2 mm. The small gaps make short circuits easy because of copper skin.

Common forming methods for metallized half-hole PCBs include CNC milling (router), mechanical punching, and V-cut. When these methods remove unneeded parts of the plated holes, they often leave copper threads and burrs on the cut PTH (plated through hole) edges. In serious cases the hole wall copper can lift or peel off. Also, during forming, PCB expansion, drill position accuracy, and forming precision can cause the half-holes on the left and right of the same unit to differ a lot in size. This makes soldering and assembly hard for customers.

Points to note for half-hole PCB process

All metallized half-hole PCB hole positions must be drilled after imaging/plating (or after pattern plating), and before etching, so that at each end of the half-hole the crossing points have a drilled hole.

The engineering department should set the MI (manufacturing instruction) flow for the half-hole process.

For metal half-holes that are formed by first drilling (or routing), then pattern plating, then a second drill before etch, think about whether outer shape routing will expose copper. Move the drilled half-hole toward the unit interior if needed.

For the right-side hole (drilled half-hole):

a. Drill it first, then flip the board (or mirror it) and drill the left-side hole.

b. This reduces the drill bit pulling on the hole copper and avoids copper loss inside the half-hole.The drill size for the half-hole depends on the distance to the outline line.

Draw the solder mask film. For routed openings, add stop points and enlarge windows by 4 mils.

Process flow

A half-hole is a metallized hole cut in half. It looks simple because you might think you only need to mill the outline on a normal board. In fact it is not simple.

Mill the half edge holes using a double V-shaped cutting path.

For the second drill, add guide holes at the broken hole edge. Remove copper skin early to reduce burrs. Switch from straight drill to slot cutter, and optimize spindle speed and feed.

Apply copper plating to the board so the round hole walls at the board edge get a layer of copper.

Make the outer layer circuit by laminating, exposing, and developing. Then do a second copper plating and tin plating so the copper layer on the round hole walls at the edge gets thicker and is covered by a tin layer that resists etching.

Form the half-hole by cutting the round hole at the board edge in half.

Strip the resist film that was pressed during lamination.

Etch the board to remove the exposed outer copper left after stripping.

Strip the tin on the board so the copper on the half-hole wall is exposed.

After forming, use red tape to hold unit boards together. Pass them through alkaline etch to remove burrs.

After the board gets a second copper plating and tin plating, cut the round edge hole in half to make the half-hole. Because the hole wall copper is covered by tin and the hole wall copper is fully connected to the outer layer copper, the bond is strong. Cutting then avoids copper lift or peeling.

After the half-hole forming is done, strip the resist and then etch. This prevents copper surface oxidation and avoids leftover copper or even short circuits. It raises the yield for metallized half-hole PCBs.

Frequently Asked Questions

A half-hole (castellated) is a plated through-hole that is milled or routed so only half the hole remains at the board edge. It creates a semi-circular plated pad used for soldering modules or board-to-board connections.

Manufacturing typically drills full plated holes, plates them, then profiles (mills) the board edge to expose half of each plated hole. The result is a plated semi-circular pad along the edge.

Common uses: module breakout boards (Bluetooth/Wi-Fi modules), board-to-board solder connections, compact modular systems, and situations where connectors are to be eliminated.

Yes — they are widely used for compact modules and fine-pitch breakout boards, but design must consider pad size, solder fillet, and solder-reflow behaviour.

Include Gerber + drill (PTH) files, clearly mark castellated holes in mechanical layer or notes, supply desired finish (e.g., ENIG), and request the fab’s DFM feedback.