What aerospace PCBs mean

Aerospace electronic parts can be either critical or non-critical. For example, the autopilot system on an airplane uses printed circuit boards (PCBs). Those boards are very important for keeping people safe. If they fail, the result can be very bad.

By contrast, a commercial airliner has circuit boards for seat control. Those boards are not critical. If they fail, people are not in danger. Still, electronic gear must be made so it can “fail safe” and not catch fire.

When you design military or aerospace electronics, plan early to follow the right rules. The parts and the materials you choose must meet the end use needs. If the product is mission-critical, expect longer lead times. The approval steps will take more time.

Manufacturing steps and material choices

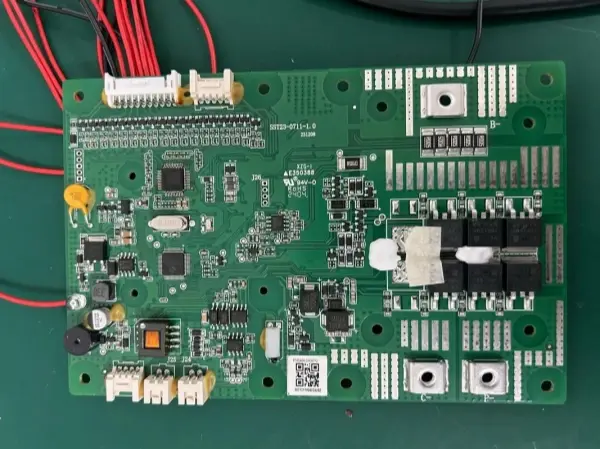

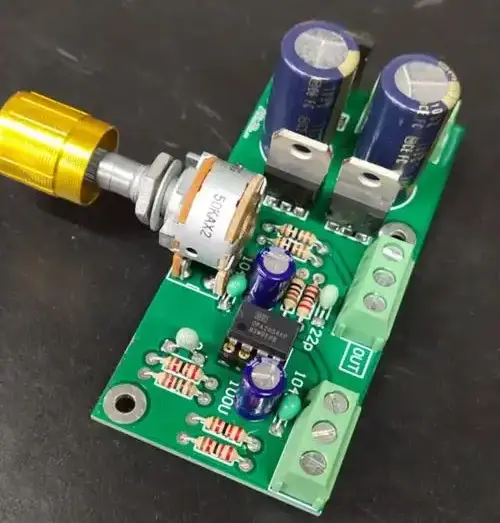

PCBA manufacturing has two main stages: board fabrication and assembly. The key first choice is which board material to use. Too often this choice does not get enough care. Many PCB design programs use FR4 as the default dielectric. FR4 works for many uses.

FR4 is sometimes good enough. In other cases it is not. For aerospace PCBs, alternate materials like polyimide may be a better choice. A better material choice comes from knowing the material traits and how those traits affect board build. Space systems must run in harsh conditions. So material choice is very important.

Main material factors for aerospace PCBs

When you pick materials for aerospace PCBs, watch these main points:

-

Strength

Space launch and flight can cause strong vibration and mechanical stress. Board strength matters. -

耐久性

Unlike most earthbound PCBs, satellite boards often cannot be repaired or changed after launch. Durability is critical. -

Thermal resistance

Boards must run under extreme heat and cold and keep working. This is one of the top needs for aerospace PCBA. -

Stability

Space temperatures can be very high or very low. Boards must resist these extremes. -

Thermal cycling

Systems must handle repeated cycles from hot to cold and back. -

柔軟性

Not all aerospace PCBs must bend. Yet many designs use multiple boards and flexible interconnects. Examples include small satellites like CubeSats. -

Chemical resistance

Outside contamination and internal contamination can harm electronic areas. Space radiation is the main worry. But other pollutants can appear, especially with moisture. To avoid this, manufacturers often purge housings with nitrogen and seal them. They also use conformal coating.

The two most common materials for aerospace boards are FR4 and polyimide. FR4 is a good general choice for many PCBs. Polyimide gives excellent flexibility and thermal traits. This makes it best for some uses. Let us look at these options from the points we listed above.

Polyimide vs FR4 for aerospace boards

Aerospace board build must follow many rules and standards. Aerospace boards must meet special appendices and specs such as IPC-6012D for rigid boards and IPC-6013D for flex and rigid-flex boards. Both polyimide and some FR4 types can meet aerospace rules. So you must look at details for your use. The table below lists what to check when you pick a material.

Note: The “FR4” items in many tables mean basic FR4. Other FR4 grades may show better traits for aerospace use.

Polyimide and FR4 differ in key ways for aerospace PCBs. One clear difference is flexibility. Polyimide is a flexible material used for flex and rigid-flex boards. FR4 is for rigid boards. Even so, polyimide is often stronger than basic FR4. This gives polyimide better durability. If you plan for extreme temperatures and thermal cycling, polyimide is a top choice. Both materials resist contamination well.

The right choice depends on the case. For some systems, polyimide is best. For others, the spacecraft internal thermal control can keep the environment stable. Then FR4 might be enough. Board design also changes the decision. Flex boards have design rules that differ a lot. For example:

-

Avoid vias in bend areas.

-

Place traces so they bend in long arcs to extend life.

-

Use 45–60 degree copper fillets at crossovers to help bend. (Some makers use different angles.)

-

Watch the number of layers vs the bend radius.

-

Use other design steps to reduce copper cracking.

Designers for different industries must adapt the material selection process. For aerospace, this step is more important. You must plan for extreme conditions.

Aerospace industry standards that apply to PCB making

A full guide for aerospace PCB standards is long. Below are the main standards you should know:

-

ISO 9100 — A basic quality management system standard. Many other standards come from ISO thinking. It focuses on customer needs, top management, QMS processes, and continuous improvement.

-

AMS2750E — Covers high temperature needs for heat treat equipment. This includes sensors, instruments, and tests for thermal processes.

-

AS478N — Shows what marks to use and where to place marks on aerospace parts.

-

AS5553A — Sets rules for the supply chain for parts that will be used in aerospace platforms.

-

AS9006A — Sets rules for software and software support that may be part of spacecraft systems.

-

AS9100D — Sets QMS needs for aerospace suppliers. It covers in-house and outsourced manufacturing steps. It stresses customer needs.

-

AS9101E — Shows how to audit and report QMS results.

-

AS9102B — Lists the First Article Inspection (FAI) baseline needs.

These aerospace standards cover areas that affect electronics and PCBs. You will also need to follow other rules that apply to your product or supply chain.

Why effective thermal conductivity of PCB matters in aerospace

Thermal control is a key issue for aerospace PCBA. Heat spread matters for all boards. In space, it is hard to move heat away by air. The vacuum makes heat transfer by air impossible. You can not fix a board that suffers thermal damage in space. So the risk is high. Overheating can make a board fail and stop the whole spacecraft from working. Your board design must include ways to make the PCB move heat away.

What is PCB effective thermal conductivity?

PCB effective thermal conductivity is the board’s ability to spread and remove extra heat. This keeps no area too hot. If a part or material gets too hot, it can fail early.

What happens if thermal conductivity is too low?

Low effective thermal conductivity can cause big problems:

-

Structural degradation

If the board’s temperature gets above a material’s limit, the board can deform or break down. Hot spots near high-power parts can form if heat does not move away. -

Component damage

Each part has a maximum temperature. If you exceed it, the part stops working or gets physical damage. -

Delamination

For multilayer boards, lamination presses layers into one structure. High temperature can break down the layers after deployment, depending on material choices. -

Fire

If extreme heat lasts long, parts or the board can ignite. Overheated insulators can arc and start a fire. This is a catastrophic result. It can destroy the board and other nearby parts.

Because of these risks, manufacturers must ensure good effective thermal conductivity for aerospace boards.

How to build aerospace PCBA for best thermal performance

Compared to ground systems, spacecraft systems cannot vent heat to the room. Electronics on a craft must move heat inside the system or to areas designed by the thermal control system (TCS). The TCS is part of the spacecraft design. To help the TCS, PCBA must remove extra heat. Use the guides below to do that well.

Thermal design guidelines for PCB effective conductivity

-

Know the temperature limits for your board in the target environment.

-

Use components that meet aerospace manufacturing standards.

-

Choose board materials that match space environment needs.

-

Run a thermal analysis on the design. This proves the board can shed heat.

-

Use special parts and materials when needed. For example, MMICs and ceramics often stand higher temperature than standard parts.

-

Follow the above steps for any board that needs high thermal performance.

These steps will help optimize the board’s ability to move heat away.

Summary and a note about Philifast

Space electronics must meet higher rules for durability and reliability. This makes their design and build different from most PCBs. These quality needs appear in the rules and standards that affect your work with a contract manufacturer (CM). Your CM should be part of the design from day one. They must make sure the boards, parts, and all processes meet or exceed aerospace standards.

Philifast offers design and manufacturing help for aerospace PCBs. We work with strict standards. We can help choose the right material, run thermal studies, and follow the needed quality checks. If you need help with aerospace PCB design, prototyping, or production, Philifast can support you from design to delivery.

Quick checklist for aerospace PCB projects

-

Plan for higher approval time when the product is mission-critical.

-

Pick materials with the needed strength and thermal traits.

-

Design flex zones carefully for rigid-flex or flex boards.

-

Run thermal analysis early.

-

Follow IPC and AS standards for aerospace use.

-

Use conformal coating and enclosure purge when needed.

If you want, フィリファスト can review your design and give feedback to make the board ready for aerospace use.