What Are PCB Gold Fingers?

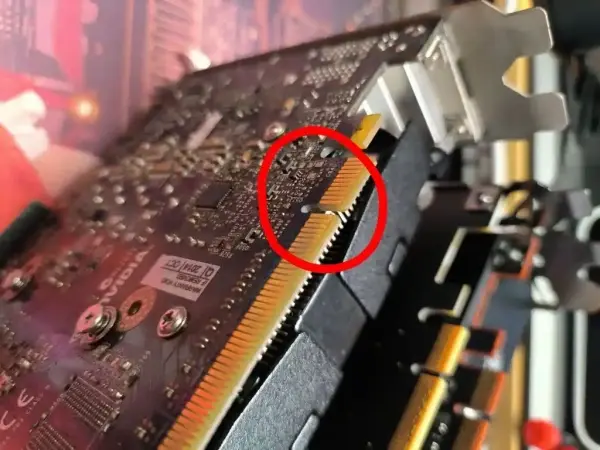

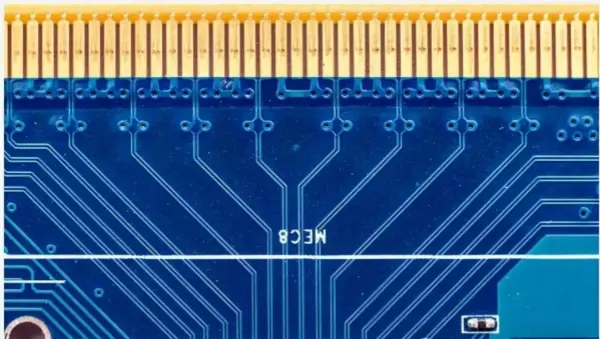

On computer memory sticks and on graphics cards, we can see a row of gold-colored conductive contacts. People call them “gold fingers.” In the PCB design and manufacturing field, gold fingers (also called “Gold Finger” or “Edge Connector”) use a connector to plug the board into a socket. The gold fingers let the board connect to other parts of the system.

A gold finger works by inserting one edge of the PCB into a connector slot. The connector’s pins touch the board’s pads or copper traces at specific places. This makes a path for signals and power to go in and out of the board. For wear resistance and good contact, the pads or copper on the board are plated with nickel and gold. Because the plated pads look like fingers, people call them gold fingers.

Types of Gold Fingers

By Shape

There are two common shapes. One is straight. The other is curved. Straight gold fingers fit memory types like DDR, DDR2, DDR3, and DDR3L. Curved gold fingers suit DDR4 and DDR5 memory sticks.

By Position

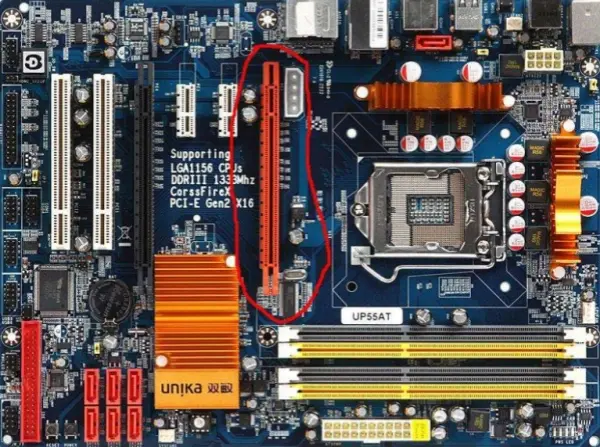

Gold fingers can be on one side or on both sides of the PCB. Single-sided gold fingers sit only on one edge of the board. Double-sided gold fingers appear on both edges. Double-sided types are common for devices that use double-slot connectors, such as PCI, ISA, and AGP.

By Length

Gold fingers can have mixed lengths in one row. Some contacts are longer and some are shorter. Designers do this to give different functions or priorities to certain pins. For example, long pads may mark power, ground, or reset pins.

What Surface Treatments Are Used for Gold Finger PCBs?

There are a few main surface treatments for gold fingers.

Electroplated Nickel-Gold (Hard Gold)

This can reach a thickness of 3 to 50 microinches. Because it conducts well, resists oxidation, and wears well, people use hard gold for gold fingers that plug and unplug often or face mechanical friction. Hard gold is expensive. So it is used only for small areas such as the gold fingers, not for the whole board.

Immersion Gold (ENIG)

Typical thickness is about 1 microinch, and it can go up to 3 microinches. Immersion gold has good conductivity, flatness, and solderability. Designers use it for high precision boards that have keys, bonded ICs, or BGA parts. If a gold finger does not need very high wear resistance, the whole board can use immersion gold. Immersion gold costs much less than electroplated hard gold. Immersion gold looks yellow.

What Is the PCB Gold Finger Plating Process?

The hard gold plating flow for PCB gold fingers goes like this:

-

Cover with blue ink (cover mask)

Cover the entire PCB surface with a blue protective mask except the gold finger pads that need hard gold. Make sure the conductive areas align with the board orientation.

-

Remove oxide from the copper pad surface

Use sulfuric acid to remove the oxide layer from the copper pad surface of the PCB. Then rinse the copper surface with water. After that, we grind or scrub to further clean the pad surface. Next, we rinse the copper surface with water and deionized water. -

Plate nickel on the PCB pad copper surface

After cleaning, we apply current to plate a nickel layer onto the gold finger pad surface. Then we rinse the nickel-plated pads with water and deionized water. -

Plate gold on the nickel-plated PCB pads

After nickel plating, we apply current to plate a layer of gold on top of the nickel. We recover the unused gold. Then we rinse the gold finger surface first with water, then with deionized water. -

Remove the blue ink

Now the hard gold on the PCB gold fingers is finished. Remove the blue ink and continue PCB processing to the soldermask printing step.

From the steps above, the gold finger process is not complex. Still, only a few PCB factories can do the gold finger process in-house.

How to Use PCB Gold Fingers

1. Edge Connector

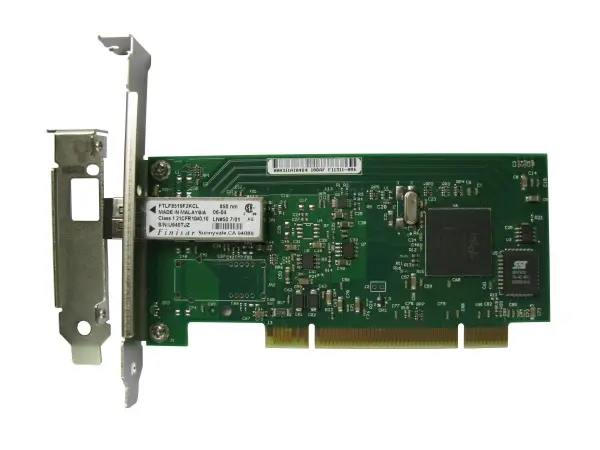

When a daughter PCB connects to a main motherboard, it plugs into one of several female slots, such as PCI, ISA, or AGP slots. Through these slots, gold fingers transfer signals between the peripheral or daughter card and the computer itself.

A PCI port socket on a PCB is often a plastic housing that opens on one side. It has pins at one or both ends of the longer edge. The connector may include a keying bump or notch to make sure the correct card type goes into the socket. The socket width is chosen based on the board thickness. On the other side of the socket, usually there is an insulation displacement connector for a ribbon cable. The motherboard or daughter card can also connect on the other side.

2. Special Adapters

Gold fingers let personal computers gain many new functions. By inserting a daughter PCB vertically into the motherboard, the computer can add better graphics or high-fidelity sound. These cards are not often unplugged and re-plugged. So the gold fingers on these cards are usually more durable than the cards themselves.

3. External Connections

Peripherals added to a computer station can link to the motherboard through PCB gold fingers. Devices like speakers, subwoofers, scanners, printers, and monitors plug into slots at the back of a computer tower. Those slots connect to PCBs that are in turn connected to the motherboard.

PCB Gold Finger Design Rules

-

Plated through-holes should be away from the gold finger. Keep any via or plated hole clear of the edge contact area.

-

Use hard gold for boards that need frequent insertion and removal. Hard gold increases wear resistance. Chemical nickel/immersion gold is cheaper than hard gold. But immersion gold wears less well.

-

Gold fingers need chamfers. A common angle is 45 degrees. Other angles like 20 or 30 degrees are also used. If the design omits the chamfer, it may cause problems during insertion.

-

Open the soldermask over the whole gold finger region. Do not use a soldermask stencil for the pins.

-

Minimum distance from solder or silver pads to the finger tip is 14 mil. It is recommended to keep pads at least 1 mm away from the gold finger area, including via pads.

-

Do not leave exposed copper on the gold finger surface. The contact surface should be plated.

-

Cut copper under the gold finger on inner layers. All inner layers under the gold finger should have copper removed. Usually the copper keepout width is 3 mm. You can do half-finger or full-finger copper cut. In PCIe designs, some evidence shows that the copper under the gold finger should be fully removed.

Gold fingers have a lower impedance than typical signal traces. Cutting copper under the finger reduces the impedance difference between the gold finger and adjacent impedance-controlled lines. This also helps against ESD.

Difference Between Immersion Gold and Gold Fingers

To put it simply, gold fingers are the brass or copper contact pieces. Immersion gold is one type of surface finish used on PCBs.

Gold resists oxidation well. Gold also conducts electricity well. On memory sticks, the parts that mate with the memory slot are plated with gold so that the signals pass through the gold fingers. Gold fingers are a set of yellow conductive contacts. These contacts are plated with gold on the surface and arranged like fingers. That is why the name comes from their finger-like look.

In plain words, a gold finger is the connection part on a memory stick that meets the memory slot. All signals pass through the gold finger.

Gold fingers are made from the copper-clad board. Then the contact areas are plated with a layer of gold by a special process.

So, simply put: immersion gold (ENIG) is a surface finish type applied to the board. A gold finger is the board part that has signals and conducts between the board and the socket.

In the market, the gold finger surface does not always use real gold. Gold is costly. Many memory sticks now use tin plating instead of gold. Since the 1990s, tin has become common. Today, most motherboards, memory sticks, and graphics cards use tin for the “gold fingers.” Only some high-performance server or workstation parts still use gold for contact points. Those parts cost much more.

概要

Gold fingers are the edge contacts on PCBs that plug into sockets. They allow the board to connect to other parts. They are made by plating the board pads with nickel and gold. There are different shapes, positions, and lengths of gold fingers for various uses. Surface finishes include hard gold plating and immersion gold. Hard gold is best for wear. Immersion gold is cheaper and still solderable. Designers must keep pads and vias away from the contact edge. They must add chamfers and open the soldermask. Inner copper under the finger should usually be cut away. Market practice moved from real gold to tin plating in many consumer products because of cost. Only special or server-level devices often still use real gold.

よくある質問

Two common approaches: electroplated hard gold (wear-resistant, used where many insertions occur) and ENIG (electroless nickel immersion gold — thinner, easier to solder but less abrasion resistant). Choose based on insertion cycles and soldering needs.

Typical hard-gold thickness for edge connectors is substantially higher than ENIG — industry guidance and connector specs often call for tens of microinches (historically 30–50 µ″ or more for heavy wear); check the connector spec or IPC guidance for your class of use.

Keep a safe clearance from the board edge (commonly ≥0.5 mm) and avoid placing SMD pads, plated holes or other copper within ~1–2 mm of the finger zone; follow your fabricator’s capability sheet for exact limits.

Common process: define edge pads in the layout → plate copper pads (PTH or exposed pads) → apply nickel barrier → electroplate hard gold (or apply ENIG) → profile the board edge so the plated pads become the connector surface. Panel design and rack/frame open borders may be required for electroplating.

Yes — use modular connectors (SMT or through-hole edge connectors), plated half-holes/castellations, or pogo-pin pads depending on cost, assembly method, and durability requirements. For high mating cycles, gold fingers usually remain the best option.