HDI boards meet the needs of high density ICs and high density interconnect assembly. They push Sản xuất bảng mạch in (PCB) to a new level. HDI is one of the hottest topics in PCB manufacturing. People who do CAM for many kinds of PCBs agree. HDI phone boards look complex, and routing density is high. CAM production is hard, and it is hard to finish fast and correct. Facing customer needs for high quality and fast delivery, I kept practicing and summarizing. I have some experience. I share it here with CAM colleagues.

Defining SMD is the first hard point in CAM

In PCB production, pattern transfer and etch will affect the final pattern. So in CAM production, we must compensate lines and SMDs according to customer acceptance rules. If we do not define SMD correctly, some SMD pads in the finished board may be too small.

Customers often design 0.5 mm CSP on HDI phone boards. The pad size is 0.3 mm. Some CSP pads have blind vias. The blind via may match a pad that is only 0.3 mm. This makes the CSP pad and the pad for the blind via overlap or cross. In this case we must be careful and avoid mistakes.

Specific steps

- Close the drill layers that correspond to blind vias and buried vias.

- Define SMD.

- Use the Feature Finder popup and Reference Selection popup functions. From the top layer and bottom layer, find pads that include blind vias. Move these pads to the T layer and B layer respectively.

- In the Reference Selection popup, on the T layer (the layer where CSP pads are), pick pads that touch the blind via by 0.3 mm and delete them. Delete top layer CSP pads of 0.3 mm in the CSP area. Then, based on the customer design for CSP pad size, position, and count, make a CSP pad yourself and define it as SMD. Copy the CSP pad to the TOP layer and add the pad that corresponds to the blind via on the TOP layer. Make the B layer the same way.

- Use the customer netlist file to find other SMDs that were missed or were defined too many times.

Compared with the usual production method, this way has a clear goal and fewer steps. This method can avoid wrong operations and finish fast and correct.

Removing non-functional pads is also a special step for HDI phone boards

Take a normal eight-layer HDI board as an example. First remove non-functional pads that match vias for layers 2–7 through holes. Then remove non-functional pads that match buried vias for layers 3–6 and vias for layers 2–7.

Steps:

- Use the NFPRemoval function to remove pads that match non-plated holes on the top and bottom layers.

- Close all drill layers except through-holes. Choose NFPRemoveUndrillRemoveUndrillLEDpads to remove non-functional pads for layers 2–7.

- Close all drill layers except buried vias for layers 2–7. Choose NFPRemoveUndrilledPads and select NO to remove non-functional pads for layers 3–6.

Using this method to remove non-functional pads is clear and easy to learn. It is best for people who just start CAM work.

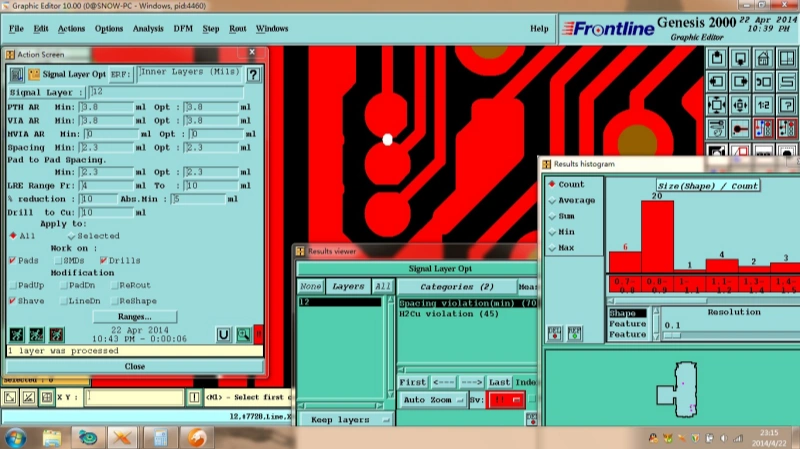

About laser drilling

Blind vias on HDI phone boards are usually microvias of about 0.1 mm. Our company uses CO₂ lasers. Organic materials absorb infrared strongly and the material ablates by heat to make holes. But copper absorbs infrared little, and copper’s melting point is high. CO₂ lasers cannot ablate copper foil. So the copper at laser hole locations is etched away using etchant. CAM must make drill exposure photoplots for this. At the same time, to make sure the second outer layer (the bottom of the laser hole) keeps copper, the distance between blind vias and buried vias must be at least 4 mil. Therefore, we must use Analysis / Fabrication / Board-Drill-Checks to find bad holes.

Via filling and solder mask

In HDI lamination stacks, the secondary outer layers usually use RCC material. The dielectric thickness is thin and resin content is low. Process tests show this rule: if the finished board thickness is over 0.8 mm, and the metallized pocket is ≥ 0.8 mm × 2.0 mm, and the metallized via is ≥ 1.2 mm, then we must prepare two sets of via fill files. That is, via filling is split into two fillings. The inner layers are planarized with resin, and the outer layer is filled with solder mask ink before the solder mask step.

During the solder mask process, vias sometimes fall on or near SMD pads. The customer asks for all vias to be filled. So vias that are exposed in solder mask or half-exposed can easily cause solder paste or grease on the pad. CAM staff must deal with this. Usually we first choose to open the via. If we cannot move the via, follow these steps:

- Add a light-through dot on the solder mask that is 3 mil smaller on one side than the finished hole.

- Add a light-through dot on the solder mask that is 3 mil larger on one side than the finished hole. (In this case, the customer allows a small amount of pad to be covered by the mask.)

Making the board outline and panelization

HDI phone boards are usually delivered as panels. The appearance is complex and the customer gives CAD files for paneling. If we draw the panel using the customer’s file with Genesis2000, it is troublesome. We can click Save As in the file and change the save type to AutoCAD R14 / LT98 / LT97 DXF (*.DXF). Then we read the *.DXF file like a normal Gerber. While reading the outline, we also read the size and position of stamp holes, locating holes, and optical fiducials. This way is fast and accurate.

Milling frame processing

When we process the milling frame, unless the customer asks to expose copper in CAM, we cut a small amount of copper inward from the frame to avoid board edge copper peeling in production. This will cause cases like figure 2A. If the two ends of A do not belong to the same net and the copper width is less than 3 mil (which may not be manufacturable), then it will cause an open. Genesis2000 analysis will not show this problem. So we must use another method. We can do more net comparisons, and in the second comparison cut the frame copper into the board. If the comparison result does not show an open, then A’s two ends belong to the same net or the width is > 3 mil and the pattern is manufacturable. If there is an open, widen the copper.

Short summary of key points

- Define SMD carefully. Use layer closing and popup tools to find pads that include blind vias. Replace small pads with correct CSP pads, and copy to top and bottom layers. This avoids overlap and errors.

- Remove non-functional pads step by step using NFP removal tools. This is clear and good for new CAM staff.

- For laser drilling, know that CO₂ lasers do not ablate copper. Use etch and make drill exposure photoplots. Keep blind and buried vias at least 4 mil apart and run board drill checks.

- Make via fill files when board thickness and hole size meet the rule. Split inner and outer fills as needed. Handle vias near SMDs in solder mask by adding proper light-through dots.

- For panel DXF reading, convert CAD to DXF and read it like Gerber to get outline, stamp holes, and fiducial positions fast and right.

- For milling frame copper, test nets and widen copper if comparisons show opens.

This method has clear goals and fewer steps. Use it to reduce mistakes and to speed up correct CAM production for HDI phone boards.