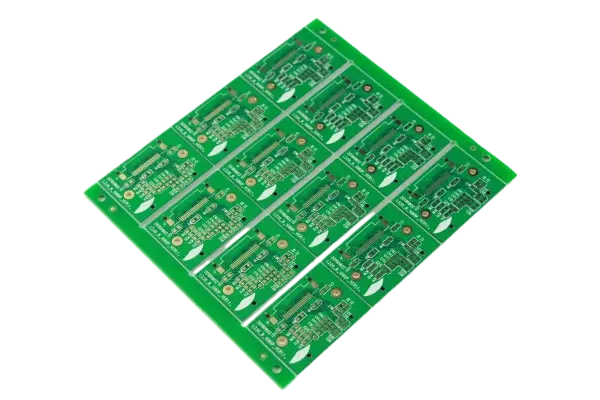

One-Stop PCBA & Turnkey Assembly Solutions

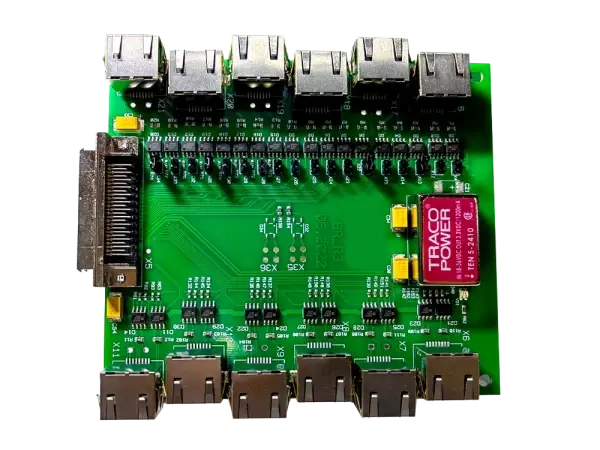

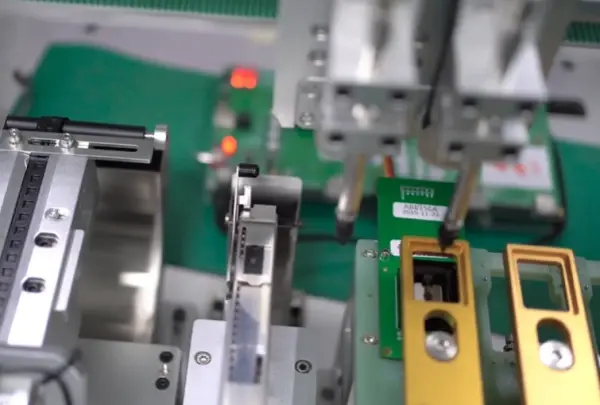

Philifast offers full-service PCBA processing and turnkey assembly: SMT placement, post-reflow through-hole (DIP) insertion, conformal coating, testing, final assembly and packaging — all under one roof.Philifast offers full-service PCBA processing and turnkey assembly: SMT placement, post-reflow through-hole (DIP) insertion, conformal coating, testing, final assembly and packaging — all under one roof.

Our high-quality PCBs and assembled boards are widely used in various industries, including consumer electronics, automotive systems, medical devices, industrial control, telecommunications, LED lighting, and smart home technology. Our boards deliver consistent performance and reliability, perfectly suited for complex and high-demand applications.

About US

Shenzhen Philifast Electron Co., Ltd. Found in 2005. Through more than 10 years of continuous development, the company has introduced the most advanced production equipment, and established a professional engineering team, accumulated abundant experience of production and management during the production. Our company has complete quality management system, a full set of supply chain system, and achieved large-scale production. Our customers market cover all over the world, the main products and technologies are exported to European and American markets. All products comply with IPC and UL standards.

Trusted PCB & PCBA Manufacturer

At Philifast, we combine advanced manufacturing capability with over two decades of engineering experience to deliver reliable PCB and PCBA solutions.Our commitment to quality, precision, and customer satisfaction has made us a trusted partner for global businesses seeking dependable electronic manufacturing services.

130+

Global Clients

20 Yrs.

Industry Expertise

200+

Professional Team

PCB Services

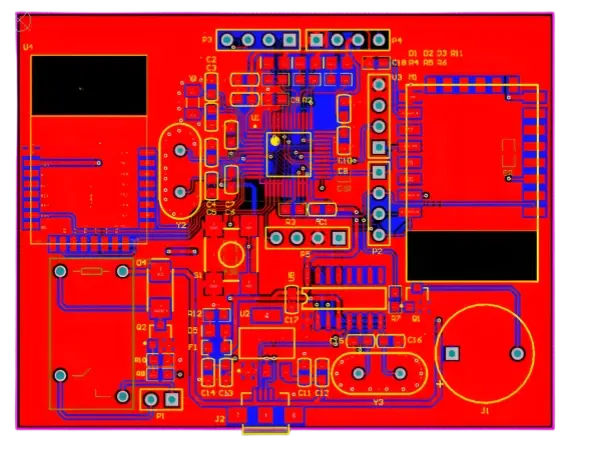

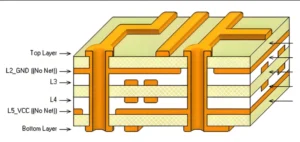

At Philifast, we provide end-to-end PCB and PCBA services to bring your electronic designs to life. From prototype development to mass production, our solutions cover every stage — including PCB fabrication, assembly, component sourcing, and testing.Our engineering team ensures high precision, reliability, and fast turnaround through advanced manufacturing processes and strict quality control. Whether it’s single-layer, multilayer, or complex boards, we deliver consistent results that meet international standards and your project requirements.With integrated services like BGA assembly, cable harnessing, and IC programming, Philifast simplifies your supply chain and helps you achieve seamless, cost-effective production.

PCB Prototyping

Layers: 1–40

Certifications: ISO 9001, ISO 13485, IATF 16949

Minimum hole size: ≤ 0.2 mm

Board thickness: 0.1–5.0 mm

RoHS certified

SMT, DIP, BGA assembly

Testing: AOI, ICT, FCT

Special processes: BGA rework, 3D SPI, X-ray solder joint analysis

Component Sourcing

Authorized distributors

Genuine original parts

Large stock on hand

10 years of sourcing experience

Free alternative part options

Up to 40 layer

30+ engineers, avg. 8 years experience

Seamless handoff from prototype to production

3 rounds of DRC checks

IC Programming

Supported file types: HEX, BIN, S19, etc.

Software: ST-Link Utility, J-Flash, OpenOCD, etc.

Methods: ICP (In-Circuit Programming) and offline programming

Programming encryption and code protection

Custom wire and cable assembly

Connectors and plug-in solutions

Industrial wire harness

USB, SAS, DVI & DP cables

Request Free Quotation

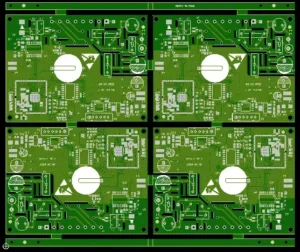

From Files to Finished Boards

Philifast follows a structured workflow designed to deliver the best PCB assembly solutions for every client. As a trusted PCBA manufacturer, we carefully review all your project files to ensure every detail is properly handled. Our experienced engineering team thoroughly checks Gerber files and BOM lists, identifying potential risks and offering optimization suggestions for your confirmation.

Once all details are verified, we move forward with component sourcing, assembly, inspection, and testing — each step carefully planned and monitored to meet strict quality and delivery requirements. Our PCBA services aim to minimize errors, shorten lead times, and ensure stable and reliable results.

From prototype verification to mass production, Philifast provides one-stop PCBA services in China with precision, flexibility, and full transparency. Customer satisfaction remains our top priority as we build long-term, trusted partnerships.

Send Files

Send your PCB design files via email for quotation.

Confirm Order

Review and approve the quotation before production.

Make Payment

Pay safely via bank transfer or PayPal.

Production

Your PCBs and assembly will be processed as scheduled.

Delivery

We ship worldwide with reliable courier services.

After-Sales

Receive your boards and enjoy full after-sales support.

Why choose us

At Philifast, we do more than build PCBs — we build partnerships. We work side by side with our clients to deliver reliable, high-quality PCB and PCBA solutions. Our goal is to be your trusted manufacturing partner, helping you bring every idea to life with speed, precision, and care.

Online quote & one-to-one service

Fast online quotations plus dedicated technical and account managers to handle your project from quotation to delivery.

Quality first

Certified to IATF 16949, ISO 13485, ISO 9001, ISO 14001 and ISO 45001. We follow standardized production control to deliver consistent, compliant results.

Advanced production lines

7 SMT lines (Yamaha YRM20), 2 DIP lines, manual soldering and wave soldering. Full inspection suite including X-Ray, AOI and SPI for reliable mass production.

Best components

- 10+ years sourcing experience; authorized distributors only

- Genuine parts from Digi-Key, Mouser, RS and authorized manufacturers

- Clear substitute recommendations—used only after your approval

One-stop PCB & PCBA service

From PCB design and material selection to SMT/DIP assembly, cable harnessing, programming and full testing—we manage the whole process for you.

Fast, reliable delivery

Optimized production planning and clear project tracking ensure fast turnaround and on-time delivery for both prototypes and volume orders.

Frequently Asked Questions

Prototypes start from 1 PCB. Small runs and mass runs depend on board type and process. Typical production MOQ is 10–100 pcs. Tell us your board details and qty for a firm answer.

Typical times: prototype 24–72 hours, small runs 5–14 days, mass production 14–30 days. Time depends on layers, parts, testing, and order size. For rush work, contact sales.

We accept bank transfer (T/T), PayPal, and credit card by agreement. For large orders we accept Letter of Credit (L/C). Other methods can be arranged on request.

Yes. We offer expedited options. Rush service costs more. Tell us your deadline when you submit files. We will confirm lead time and fee.

We buy from authorized distributors and factory agents. All parts are new and original. If we suggest substitutes, we explain them. We use suppliers like Digi-Key, Mouser and authorized sources.

We hold IATF 16949, ISO 13485, ISO 9001, ISO 14001, and ISO 45001. We test with AOI, X-Ray, ICT, FCT, and SPI. Certificates are available on request.

We pack boards with anti-static and protective materials. We offer air and sea shipping. We can arrange DHL, FedEx, or ocean freight and support export customs documents. Tell us your delivery address for shipping cost.

Yes. We can sign an NDA on request. Send your NDA or ask us to provide a standard NDA. Files stay private and are only used for your project.