fr4 — definition and meaning

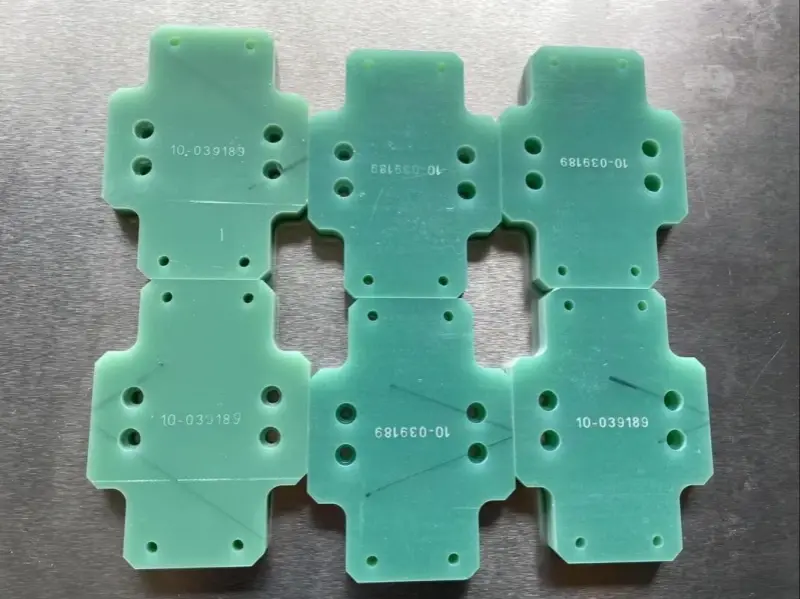

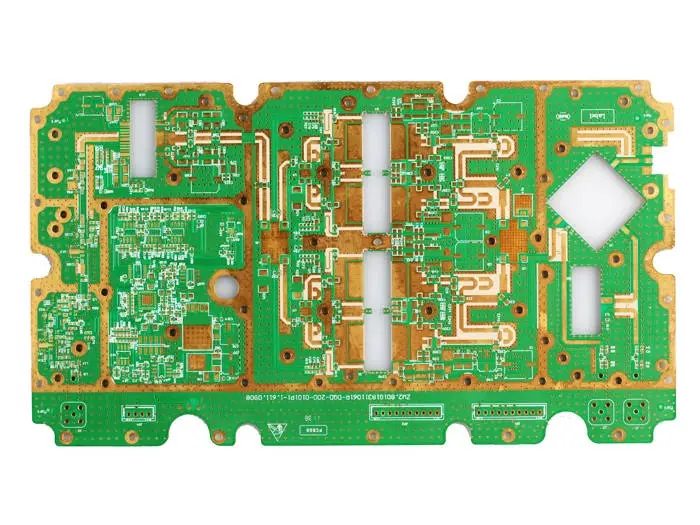

fr4 is the code for the flame-retardant rating of a glass-fiber reinforced epoxy copper clad laminate. It means the resin must stop burning on its own after being ignited. fr4 is not the name of one specific material. It is a material grade used for PCBs (printed circuit boards).

composition and common types

There are many kinds of fr4 materials used in normal PCBs. Most are composite materials made from a so-called tetra-functional epoxy resin, plus fillers and glass fiber.

Example: if a PCB spec reads fr4 T:1.0 D/S, it means: fr4 flame-retardant grade, T:1.0 means thickness 1.0 mm, D/S means double side. In other words, the board material is an epoxy glass cloth double-sided copper clad laminate, 1 mm thick, double sided.

fr4 — key properties and classifications

Technically, fr4 laminates have a set of key specs. These include:

- flexural strength and peel strength, and thermal shock performance;

- strong flame retardance;

- volume resistivity and surface resistivity;

- dielectric constant (Dk) and dissipation factor (loss tangent);

- glass transition temperature (Tg);

- dimensional stability, maximum use temperature, and warpage.

These properties together define fr4 performance in PCB making.

other common PCB base materials

◉ Glass cloth based boards

- Glass cloth boards: fr4 and fr5

Both use special electronic fabric soaked in epoxy (or epoxy-phenolic) resin. Then they are cured under high heat and pressure. fr4 is the most used board in PCB making. It has good electrical properties, good mechanical strength, and heat resistance. It is widely used in multilayer PCB production.

◉ Paper based boards

2. Paper boards: fr-1, fr-2, fr-3

Phenolic paper boards use phenolic resin as the binder and wood-pulp fiber cloth as surface reinforcement. They are made under high heat and pressure.

◉ Composite boards

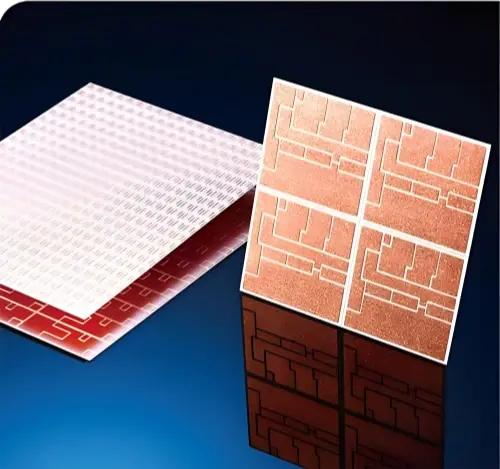

3. Composite boards: CEM-1 and CEM-3

Composite boards include the CEM series of copper-clad laminates. CEM-1 uses epoxy paper as the core. CEM-3 uses epoxy glass non-woven fabric as the core. These CEM boards are easy to process. They have good flatness, dimensional stability, and precise thickness. Their mechanical strength, dielectric properties, water absorption, and resistance to metal migration are all better than paper boards. Notably, CEM-3 can reach about 80% of fr4’s mechanical strength but usually costs less.

◉ Special material boards

4. Special boards (for example, ceramic and metal)

These include ceramic substrates and metal core boards. They have special properties for applications that need higher material performance.

advantages and limits of fr4

Since I started designing PCBs, fr4 has been the standard board material. At first, some designers called every board “fr4” whether it was or not. fr4 is a flame-retardant, type-4, glass-fiber reinforced epoxy laminate. It is cost-effective. It is a good electrical insulator. It is strong in both dry and humid conditions. It is also easy to make into boards. For these reasons, fr4 is a common choice for building PCBs.

fr4 has limits. It can run into problems when there is too much power, voltage, or heat. If you push it beyond its limits, its dielectric properties will drop. That means the material will lose insulation and start to conduct. Another issue is keeping stable impedance in high-speed designs. fr4’s dielectric constant can vary across board length and width. As design speeds rise, signal loss that was acceptable in low-speed boards can become too high on fr4 boards.

is fr4 the best choice for high-speed PCB design?

When we take on a project outside our comfort zone, we learn new limits. For me, that day came when my boss asked for a high-speed board. I knew high-speed design brings limits we do not see in normal circuits. First, I made a schematic fit for high speed. Then I focused on whether the high-speed prototype should use fr4 or a more specialized material. Before choosing, note that this text uses “high-speed” for anything above 50 MHz. These are the material concerns at that frequency range.

High-speed designs have stricter rules for signal integrity. You must control routing closely to meet those rules. But the board material itself is part of the signal-integrity equation. So the material for high-speed boards should have tight Dk tolerance and other controlled properties to help control impedance. If impedance varies across the design, high-speed signals will reflect energy back as they travel and the signal will distort. Also, low loss tangent helps keep the signal strong. Finally, thermal stability helps ensure dielectric properties do not break down.

how specialized high-speed materials compare with fr4

Special high-speed materials, such as thermoset hydrocarbon laminates and PTFE laminates, often give better and more reliable performance in higher-frequency designs than fr4. Below are some key benefits of these materials:

- Reduced signal loss. As transmission line frequency goes up, signal loss grows. High-speed laminates have much lower loss tangent than fr4. Some materials, like near-pure PTFE laminates, are an order of magnitude better. Lower loss tangent is a key factor in reducing signal loss.

- Tighter impedance control. Traditional materials like fr4 cannot hold dielectric constant (Dk) as tightly as high-speed materials. fr4 Dk can vary by ±10% or more. Materials like PTFE can keep Dk within about ±2% or better.

- Quản lý nhiệt tốt hơn. Some high-speed laminates (for example thermoset hydrocarbon laminates) have much better thermal conductivity than fr4. If your design needs to manage heat, these laminates are worth studying.

- Giảm khả năng hấp thụ độ ẩm. Water has dielectric effects. Even small moisture in a PCB can change electrical performance of high-frequency circuits. Although the text says fr4 moisture absorption is near 50%, some high-speed materials (for example some PTFE laminates) can have much lower moisture uptake, near 2%, and this helps maintain stable electrical behavior.

- Độ ổn định kích thước cao hơn. Các thiết kế mạch in dày đặc, tốc độ cao đòi hỏi kiểm soát kích thước chặt chẽ. FR4 được biết đến với độ ổn định kích thước tốt, nhưng một số vật liệu tốc độ cao khác cung cấp hiệu suất tổng thể tốt hơn cho các thiết kế có dung sai nghiêm ngặt. Trong trường hợp này, các tấm laminate hydrocarbon nhiệt rắn có thể là lựa chọn tốt hơn.