مقدمة

When a printed circuit board (PCB) goes through reflow soldering, it often bends or warps. If the problem is serious, parts can lift, solder joints can fail, or components can stand on end. This article first explains the risks of PCB warpage. Next, it looks at the main causes of warpage. Last, it lists practical ways to reduce or prevent warpage. Read on for clear, simple steps and reasons.

The Risks of PCB Warpage

If a PCB is not flat on an automated surface-mount line, the machine may not place parts in the right spot. Parts may not go into holes or land on SMD pads. In some cases, the automatic insertion machine can be damaged. After parts are mounted and soldered, a warped board makes it hard to trim leads cleanly. The board may not fit into the case or plug into sockets. So assembly shops find warpage a big problem.

Surface-mount technology (SMT) is moving toward higher accuracy, higher speed, and more automation. This raises the flatness need for PCBs. Flatness matters because modern machines expect the board to be stable and accurate during placement and soldering.

In practical terms, IPC standards say the maximum allowed warpage for boards with surface-mount devices is 0.75%. For boards without surface-mount devices, the limit is 1.5%. Some companies set stricter limits to meet high-speed, high-accuracy assembly. For example, some customers ask for a maximum warpage of 0.5% or even 0.3%.

What Causes PCB Warpage

A PCB is made from different materials, such as copper foil, resin, and glass fiber. These materials act differently under heat and stress. When they are pressed and cured together, leftover thermal stress can cause warpage. In addition, PCB manufacturing has many steps that add heat and mechanical load. These steps include lamination, drilling, cutting, baking, and soldering. All of these can change board shape. Because many factors can cause warpage, finding the main cause is often hard.

Uneven Copper Area

Large copper areas are often used for ground or power planes. If these large copper areas are not spread evenly on the board, heat absorption and heat release will be uneven. When the board heats up and cools down, parts of the board expand and shrink at different rates. This unequal expansion creates stress and can cause the board to warp. If the board reaches its glass transition temperature (Tg), the material softens and can take a permanent shape change.

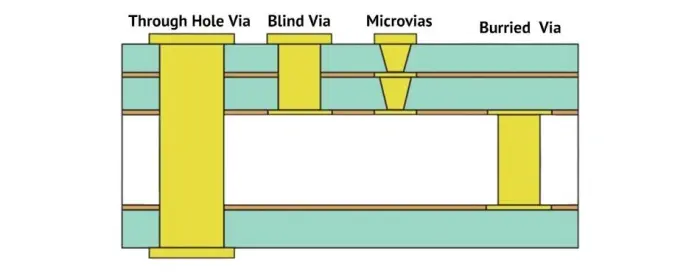

Vias and Layer Ties

Most modern PCBs are multi-layer. Layers are joined by فياس. Vias come in three types: through holes, blind vias, and buried vias. Where vias tie layers together, they limit how the board can expand and contract. This constraint can cause local stress and can make the whole board bend or warp.

Board Weight and Component Weight

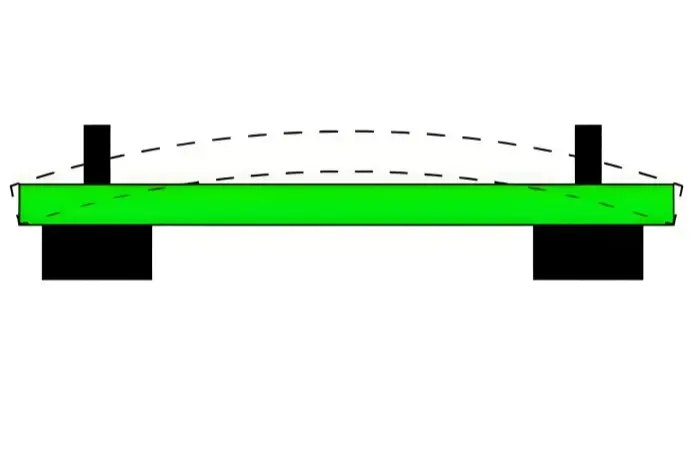

Reflow ovens often move PCBs on chains that support the board at the edges. If the board has very heavy parts or is very large, its own weight can make the center sag. This sagging leads to bow or bend during heating and can remain after cooling.

V-Cut Depth and Tab Design in Panels

V-Cut is a method to separate boards in a panel. V-Cut reduces structural strength in the panel. The cut areas are weak and can warp more easily. Deep V-Cuts or many V-Cuts on one panel increase the risk of warpage during processing.

Material and Stackup Differences

A PCB is made from cores, prepregs, and outer copper foils. During lamination, the cores and foils heat up and may deform. The amount of change depends on each material’s coefficient of thermal expansion (CTE).

Copper foil and FR-4 base material have different CTE values. For FR-4, the Z-axis CTE below Tg is different than the CTE above Tg. Above Tg, the resin softens and expansion can be much larger. High-Tg materials change less at high temperature and hold shape better.

When different cores have different copper patterns, thickness, or materials, they expand by different amounts during lamination. If two cores with very different CTEs are bonded by prepreg and cured, the board may lock in unequal stress. When the board cools, those differences cause the board to bend toward the side that shrank less.

Thermal Cycling During Lamination

During lamination, the temperature rises and the prepreg flows, fills copper patterns, and then cures. While the prepreg is still soft, the cores can expand freely. But after curing, the layers are stuck together. If the cores had expanded different amounts, the cured assembly holds that mismatch. When the board cools, the mismatched shrink rates remain and cause permanent warpage.

Manufacturing Steps That Add Stress

PCB process steps add both thermal and mechanical stress. Thermal stress mainly comes from lamination. Mechanical stress comes from stacking, handling, and baking. Important process points include:

- Incoming copper-clad laminate: These are symmetric in structure and usually do not warp during lamination, but the press has temperature differences across the plate. These local differences can create small local stresses that show up later.

- Lamination: This is the main source of thermal stress. In a PCB stackup, layer patterns vary and so do prepreg amounts. These differences make thermal stress higher and harder to remove. During drilling, routing, and baking, stored stress can be released and cause the board to warp.

- Solder mask and legend baking: Solder mask inks cure around 150°C. This temperature can be above the Tg of low- to mid-Tg materials and make the board more flexible. While boards are on racks in the oven or under airflow, they can bend under their own weight or the oven’s air. This adds to warpage.

- Hot air solder leveling (HASL): HASL is a rapid heat event. Typical solder pot temperature is high and the board goes from room temperature into high heat and then is washed and cooled. The rapid heat and cool cycle adds thermal stress and can cause micro-strain and larger warp.

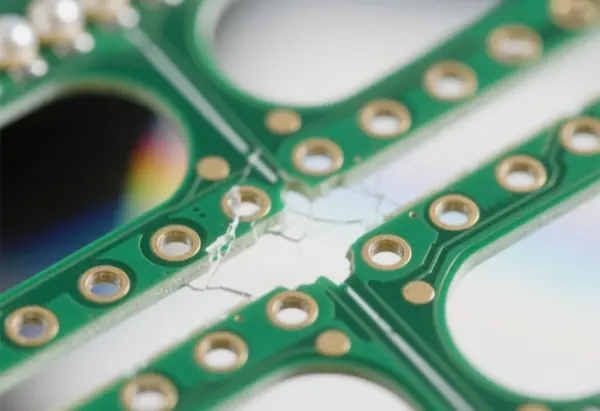

- Storage and handling: Boards are often stored vertically on racks. If the racks are too tight, or boards are stacked, they can get bent by mechanical force. Thin boards under 2.0 mm are more affected.

How to Reduce PCB Warpage

Below are practical methods to reduce warpage during PCB production and assembly.

1. Reduce Temperature and Slow Heating/Cooling

Because temperature is a main source of stress, lowering oven temperature or slowing the rate of heating and cooling in the reflow process helps. If the board heats and cools more slowly, the stress from thermal expansion is lower and warpage is less likely. Note that changing the temperature profile may affect soldering quality or cycle time, so check for side effects.

2. Use High-Tg Materials

Tg is the glass transition temperature. Above Tg the material softens and becomes rubber-like. Materials with low Tg soften faster and for longer time at reflow. Using higher-Tg base material increases the board’s resistance to deformation under heat. High-Tg materials cost more but they help avoid warpage and other heat-related problems. High-Tg is commonly used in lead-free processes.

3. Increase Board Thickness

Many consumer products aim for thin, light PCBs. Boards as thin as 1.0 mm, 0.8 mm, or 0.6 mm are common now. Thin boards are harder to keep flat through reflow. If the product allows, use a standard 1.6 mm board thickness. Thicker boards resist bend and sag and lower warpage risk.

4. Reduce Board Size and Panel Count

Because reflow ovens often support the board at edges, larger boards can sag under their own weight. For large panels, try to orient the long edge along the support chain so sag is reduced. Also, use fewer boards per panel when possible. Make the board pass through the oven with the narrow edge forward to reduce sagging.

5. Use Reflow Carriers or Trays

If the other methods are not enough, use reflow carriers or templates. A carrier holds the PCB flat during heating and cooling. The carrier keeps the board from moving until the board cools below Tg and regains stiffness. If one-side carrier is not enough, use a two-piece carrier that clamps the board between top and bottom plates. Carriers cost money and require extra handling time, but they cut warpage well.

6. Replace V-Cut with Routed Tabs or “Mouse Bites”

Since V-Cut can weaken a panel, reduce the depth of V-Cuts or use solid tabs or routed rails. Solid tabs or stamped holes keep panel strength high and lower warpage risk. When V-Cut must be used, keep cuts shallow and leave enough panel frame to support the board.

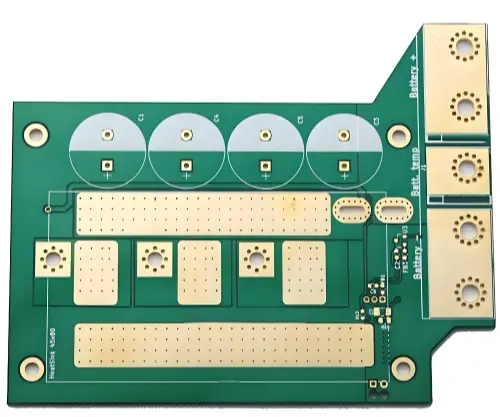

7. Choose Materials Carefully and Design Symmetry

Choose base materials that have similar CTE and that match the process needs. Design the copper patterns to be as symmetric as possible between top and bottom and across layers. Avoid large unbalanced copper pours on one side while the other side is sparse. Use internal plane splits or thermal reliefs to balance copper distribution when possible.

8. Use Symmetric or Thoughtful Stackups

A symmetric stackup (mirror-like layering) reduces imbalance and lowers warpage. If asymmetric stackups are needed for electrical reasons, try to plan the layer order so the overall structure remains balanced. When core materials differ, layering and tool board placement in the lamination stack can be adapted to reduce stress.

9. Optimize Lamination Parameters

Lamination settings matter: press temperature profile, hold time, and cooling control all affect stress. Use presses that can control cooling at the end of the hot cycle. A hot-press with integrated cooling is better than a hot press that transfers the stack to a cold press quickly. Also, use symmetric stacking of tool plates and buffer materials around the PCB stack during lamination.

For boards that must use non-standard materials or asymmetric structures, try asymmetric stacking in the press. The idea is to place buffer materials or tool plates in a way that balances heat flow so both sides warm and cool at matching speeds. This may reduce the CTE mismatch effect. Post-laminate curing or post-bake steps also help stabilize the board.

10. Avoid Oven Rack Mistakes and Control Bake Flow

When baking solder mask or legend inks, do not stack boards in a way that lets lower boards bend under the weight. Make sure the board orientation in the oven matches the airflow so wind does not bend boards. In hot-air leveling, ensure the board is laid flat and allowed to cool at least 30 seconds before water wash to avoid sudden cool-down that causes thermal shock.

11. Manage Storage and Handling

Store boards on racks that do not bend them. Avoid stacking many racks in small spaces where boards press on each other. Use proper pallet and rack spacing so boards do not get squeezed and deformed by plasticity. Some deformation from storage may not be fully removed by later flattening steps.

12. Pre-Shipping Flattening (Final Planarization)

Most PCB makers run a final flattening step before shipping. This step can be mechanical flattening or heat flattening under weight. Because solder mask and surface coatings affect how heat flattening works, control the bake temperature and time carefully. For most boards, heating to just below or near Tg and using weight during cooling helps flatten boards. For high-Tg materials, you may need higher temperatures but watch for ink and coating limits.

Adding pressure during bake and slowing the post-bake cooling time both help the flattening effect. These settings must match the board material and coating. Final flattening can reduce warpage significantly but is not a full fix if earlier process steps caused large built-in stress.

Production and Design Notes

When the board uses low-Tg material, the defect rate for warpage tends to be higher than for high-Tg material. High-Tg materials usually include fillers and have lower CTE than low-Tg types. During downstream processing, the usual bake temperature near 150°C affects low-Tg boards more.

In design, avoid structural asymmetry, material asymmetry, and uneven copper patterning. These design issues increase warpage risk. Also, core-to-core lamination (bonding multiple cores directly) often leads to more complex stress than single-core with copper foil lamination. Core stacks with three or more cores show a higher failure rate in warpage tests than simpler structures.

Panel frame design also affects warpage. A continuous large copper frame at the panel edge can make the whole panel rigid during lamination and keep stress in place. This stress may release after routing and make single boards warp more. A non-continuous frame with copper dots or blocks tends to release stress gradually and may lead to less single-board warp after routing.

Lamination Strategy

Lamination is key to warpage control. Use proper press selection, set correct parameters, and plan the stack arrangement to reduce stress. For symmetric structures, use symmetric stack and symmetric tool plates. A hot press that cools the stack inside the press is better than moving to a separate cold press. Cooling while the material is still supported reduces stress release that leads to warpage.

For asymmetric boards that must be made, experiment with asymmetric tool stacking and post-cure steps. The method uses buffer material placed in a way that causes both board surfaces to heat or cool differently so the final shrinkage balances out. After lamination, adding a secondary cure or a flattening step and checking the board thickness tolerance can get the part within customer specs.

Other Process Controls

Beyond lamination, remember other high-heat steps such as solder mask curing, legend curing, HASL, and reflow. These steps should be controlled to avoid rapid heat and cool cycles that make stress. Use appropriate oven profiles, give more time for heating and cooling, and allow boards to rest or cool on flat surfaces. During storage, avoid stacking that bends boards.

Final Flattening and Shipping

Before shipping, most factories flatten boards to remove process-induced warpage. Mechanical flattening or heat flattening under weight improves flatness. For typical materials, a flattening bake near 140–150°C works well because it sits above the Tg of many standard boards. For high-Tg boards, this bake is less effective and might be increased carefully. Use pressure and longer cooling time to improve results. The flattening step can make a large difference in the final flatness that the end customer sees.

Summary and Practical Checklist

Warpage is a common PCB issue. It comes from material mismatch, thermal cycles, handling, heavy parts, and panel design. To reduce warpage:

- Use high-Tg material when possible.

- Keep board stackups symmetric when you can.

- Balance copper area top and bottom.

- Use thicker boards if product allows.

- Reduce panel size or limit boards per panel.

- Orient panels so the long edge is supported in the oven.

- Slow heating and cooling in reflow and other ovens.

- Use reflow carriers or two-piece trays for fragile or large boards.

- Replace or reduce deep V-Cuts with routed tabs or stamped holes.

- Optimize lamination settings and use hot-to-cold integrated presses when possible.

- Avoid stacking boards or compressing them during bake.

- Add a final flattening step under controlled heat and pressure.

If you follow these steps in design and in production, you will cut the warpage rate and lower rework and assembly failures. Each board is different, so run small tests for new stackups, materials, or panel schemes before full production. This moves risk out of mass runs and keeps quality high.

Closing Notes

Address warpage at the design stage and during process planning. Small changes in copper layout, paneling strategy, or lamination order can have big effects. If a board still warps, use carriers, increase thickness, or change material grade. Work with board suppliers to pick a combined approach of design rules and process controls. That will make assemblies more reliable and lower costs from failed parts and rework.