One-stop PCB

Manufacturing

Our impact

Our PCB Manufacturing Services

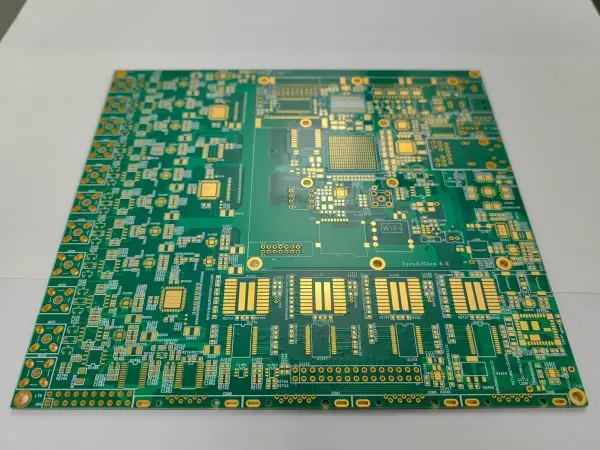

From prototype to mass production, we deliver precise, reliable PCBs across 1–32 layers using modern fabrication and strict quality control.

Design File Handling

Our expert team parses Gerber files, performs DFM manufacturability analysis, and supports multi-format conversion to ensure your design matches PCB fabrication processes.

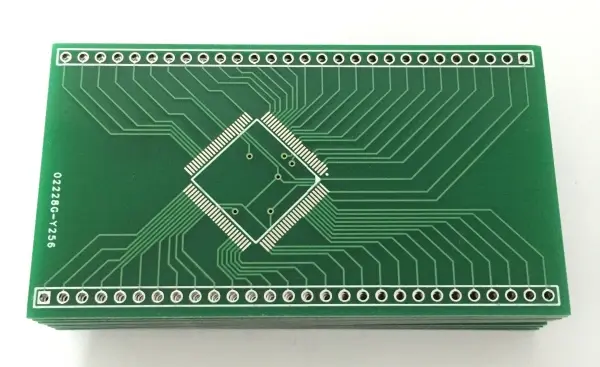

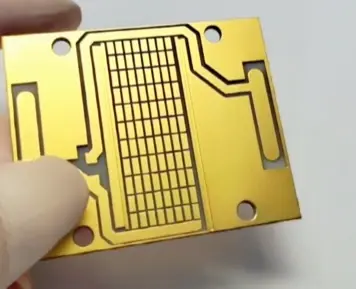

Full-Range PCB Production

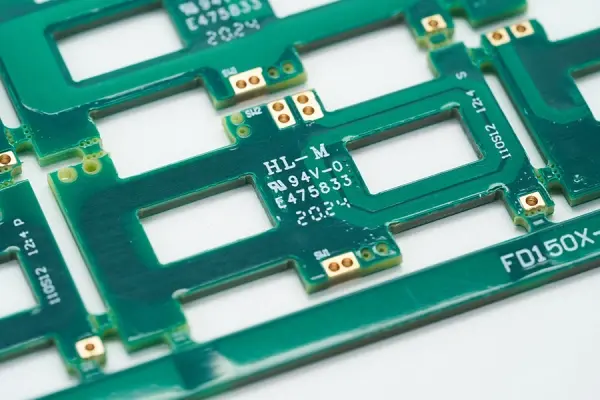

We offer full-range fabrication for single/double-sided boards, multilayer PCBs and flexible PCBs, plus specialty processes and multiple surface finishes to fit varied applications.

Multi-Level Inspection & Validation

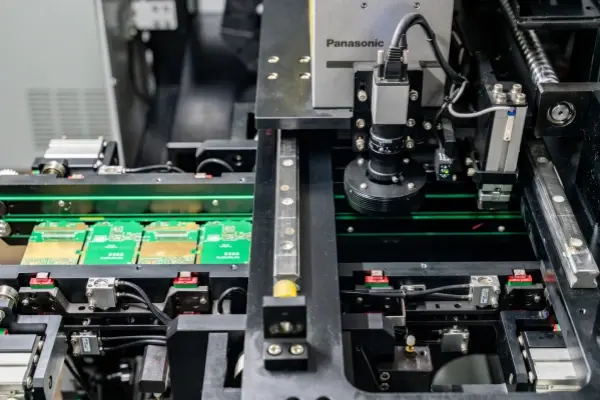

First-article approval before production, AOI monitoring during assembly, and final multi-dimensional inspection reports (AOI, X-ray, functional testing) to guarantee reliable quality.

Why Us

Your Trusted PCB Manufacturer

We are committed to being your reliable PCB manufacturing partner. Our dedicated quality management team follows a comprehensive approach that includes advanced planning, risk prevention, real-time monitoring, corrective actions, and process standardization. With state-of-the-art testing equipment, we ensure full control of process parameters and product quality from start to finish.

20

Years of Industrial Experience

Over the years, our company has successfully obtained multiple international certifications, including ISO 9001:2015, ISO 14001:2015, OHSAS 18000:2007, IATF 16949:2016, CQC, as well as UL product certification. These achievements reflect our commitment to consistent quality, safety, and environmental responsibility.

PCB Fabrication Services

PCB Prototyping

Rapid prototypes in 24–72 hours to speed product validation.

Low-cost samples for fast design verification.

High Frequency PCB

Precision impedance control and low-loss materials for RF/5G.

Keramička štampana pločica

High thermal stability and excellent dielectric performance.

Ideal for high-power, high-temperature, and precision applications.

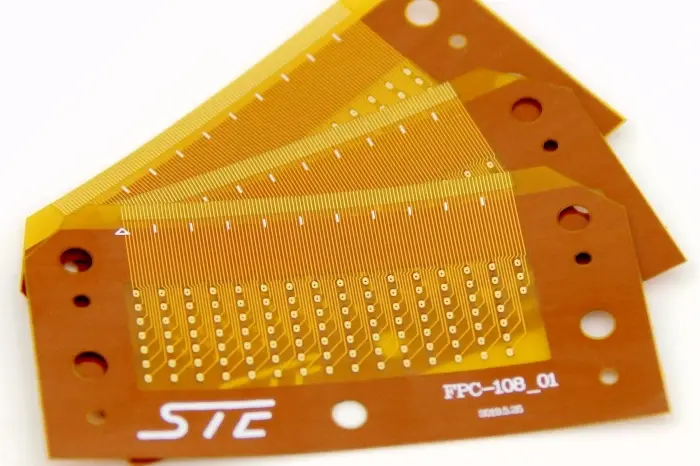

Fleksibilna štampana pločica

Compact, bendable designs for wearables and compact electronics.

Rigid-flex and multi-layer FPC solutions for complex layouts.

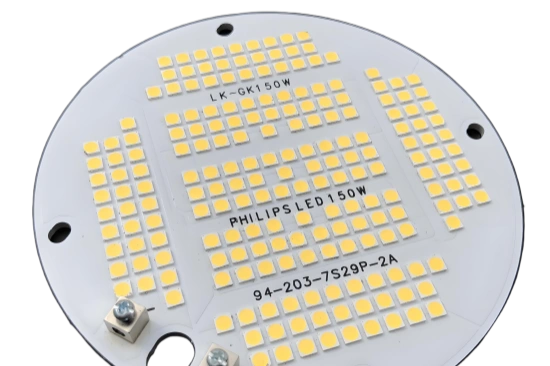

Aluminijska PCB

Metal-core boards for superior heat dissipation and reliability.

Perfect for LED, power modules, and thermal-critical designs.

Quality of service that no one can match

We don’t just make PCBs — we guarantee outcomes. From DFM checks at the design stage to final multi-dimensional inspection reports, every step is designed to reduce defects, accelerate approvals and ensure field reliability.

How we ensure it

Proactive planning & DFM — design-for-manufacturability reviews prevent issues before production.

In-process control — automated monitoring and AOI/X-ray catch deviations in real time.

Corrective & preventive actions — root-cause driven fixes and continuous process improvement.

Standardization & traceability — documented work instructions and lot tracking through every stage.

Certified & equipped

Our facilities meet international standards (ISO, IATF, CQC, UL) and are fitted with the inspection tools and SMT lines needed to deliver repeatable results for prototypes and high-volume runs alike.