Preface

Research on BGA technology began in the 1960s. IBM in the United States used it first. But BGA only became practical in the early 1990s.

In the 1980s, people wanted smaller electronic circuits and more I/O pins. Surface Mount Technology (SMT) gave circuit assembly the features of being light, thin, short and small. SMT also brought higher demands for pin pitch and coplanarity for parts with many leads. However, due to limits in machining accuracy, manufacturability, cost and assembly process, the pitch limit for QFP (Quad Flat Pack) parts was generally seen as 0.3 mm. This limit greatly restrained the development of high density assembly. Also, fine-pitch QFP parts needed strict assembly processes. That limited their use. For that reason, some US companies focused on developing and using BGA parts. They saw BGA as superior to QFP for high density needs.

What is BGA?

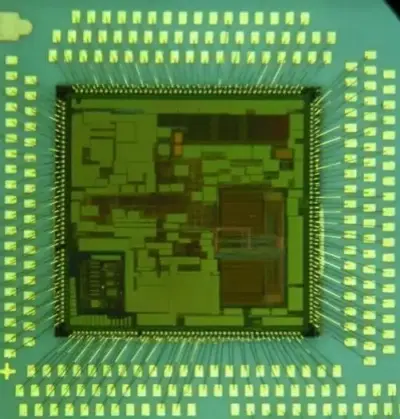

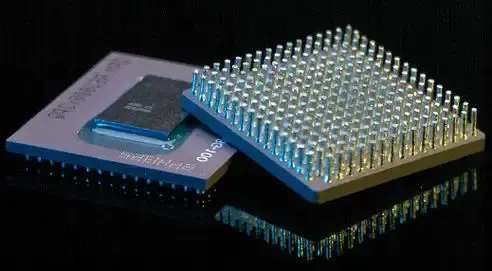

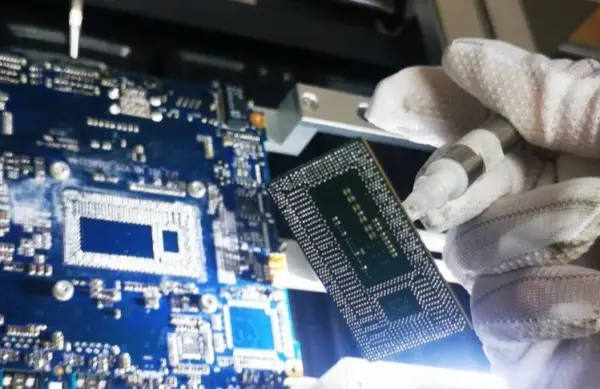

BGA stands for Ball Grid Array. In this package, solder balls are made in a grid on the bottom of the package substrate. These balls act as the I/O connections between the device and the printed circuit board (PCB). Parts packaged with this method are surface mount devices. Early CPUs used DIP packages, like some very basic microcontrollers today.

Today, with the rapid growth of the electronics industry, computers and mobile phones are common. People want more functions and stronger performance from electronic products, but they also want smaller size and less weight. This drives products toward more functions, higher performance, and smaller size. To meet this goal, IC chips must get smaller and more complex. Then circuit I/O counts rise and package I/O density rises. To meet this trend, advanced high-density packaging technologies were created. BGA packaging is one of these technologies.

Among all IC package types, BGA saw the fastest growth between 1996 and 2001. In 1999, BGA output was about 1 billion units. To date, this technology is still mostly for high density, high performance devices. It continues to move to finer pitch and higher I/O counts. BGA packaging is mainly used for PC chipsets, microprocessors/controllers, ASICs, gate arrays, memory, DSPs, PDAs, PLDs and similar devices.

Types of BGA by package material

Depending on package material, BGA devices mainly include:

PBGA (Plastic BGA)

CBGA (Ceramic BGA)

CCBGA (Ceramic Column BGA)

TBGA (Tape BGA)

CSP (Chip Scale Package or μBGA)

PBGA — Plastic Ball Grid Array

PBGA uses BT resin / glass laminate as the substrate. The package is sealed with plastic (an epoxy molding compound). Solder balls can be leaded alloys (for example 63Sn37Pb, 62Sn36Pb2Ag) or lead-free alloys (for example Sn96.5Ag3Cu0.5). The solder balls and the package body are joined without adding extra solder.

Some PBGA packages have a cavity. They come in “cavity up” and “cavity down” versions. These cavity PBGA packages improve heat dissipation and are called thermally enhanced BGA, or EBGA. Some also call them CPBGA (Cavity Plastic BGA).

Advantages of PBGA:

Good thermal match with PCB. The BT resin/glass laminate in PBGA has a coefficient of thermal expansion (CTE) of about 14 ppm/°C. Many PCBs have CTE around 17 ppm/°C. The two values are close. So thermal matching is good.

During reflow soldering, PBGA uses the self-alignment effect of solder balls. The surface tension of molten solder helps align the balls to pads.

Low cost.

Good electrical performance.

Disadvantage of PBGA:

Sensitive to moisture. Not suitable for devices that need hermetic sealing or very high reliability.

CBGA — Ceramic Ball Grid Array

CBGA has the longest history among BGA families. Its substrate is multilayer ceramic. A metal lid is sealed to the substrate with sealing solder to protect the die, wire bonds and pads. The solder ball material for the package is a high-temperature alloy labeled as 10Sn90Pb in the source text. The connection between the balls and the package body uses a lower-temperature alloy such as 63Sn37Pb.

Advantages of CBGA:

Good hermeticity and high resistance to moisture. That gives high long-term reliability.

Better electrical insulation than PBGA.

Higher package density than PBGA.

Better heat dissipation than PBGA.

Disadvantages of CBGA:

The CTE of ceramic substrate and PCB differ a lot. Thermal mismatch is poor. Solder joint fatigue is a main failure mode.

Higher cost than PBGA.

Solder ball alignment near the package edge becomes harder.

TBGA — Tape Ball Grid Array

TBGA is a cavity package. There are two ways to connect the die to the substrate in TBGA: flip-chip solder bonding and wire bonding. In flip-chip, the die is bonded onto a multilayer wiring flexible tape. Peripheral array solder balls, which act as circuit I/O terminals, are placed under the flexible tape. A thick sealing lid serves as both a heat sink and a reinforcement. This makes the solder balls under the flexible substrate more coplanar. The die is bonded to a copper heat spreader in the cavity. The die pads and flexible tape pads are connected by bonding wires. A sealant encapsulates the die, wires and flexible tape pads (by potting or coating).

Advantages of TBGA:

The flexible tape in the package better matches the PCB thermal expansion.

Reflow soldering can use the self-alignment effect of solder. Surface tension of molten balls helps align balls to pads.

TBGA is the most economical BGA package.

Better heat dissipation than PBGA.

Disadvantages of TBGA:

Sensitive to moisture.

The multiple material layers in the package can reduce reliability.

Other BGA types

Other package forms include:

MCM-PBGA (Multiple Chip Module PBGA)

μBGA (micro BGA), a chip-scale package

SBGA (Stacked Ball Grid Array)

etBGA (extra thin BGA) where package height is about 0.5 mm, near chip thickness

CTBGA, CVBGA (Thin and Very Thin Chip Array BGA) — thin and very thin BGAs

Standard rework

Principle of standard SMD rework systems:

They use hot air to concentrate heat on the pins and pads of surface mount devices (SMD). This melts solder joints or reflows solder paste so parts can be removed or soldered. Different vendors’ rework systems differ mainly by heat source and the hot air flow pattern. Some nozzles blow hot air above the SMD. From the device protection point of view, it is better to have airflow circulate around the PCB. To prevent PCB warpage, choose a rework system that can preheat the PCB.

BGA Rework

This section summarizes BGA rework steps using an HT996 system as an example.

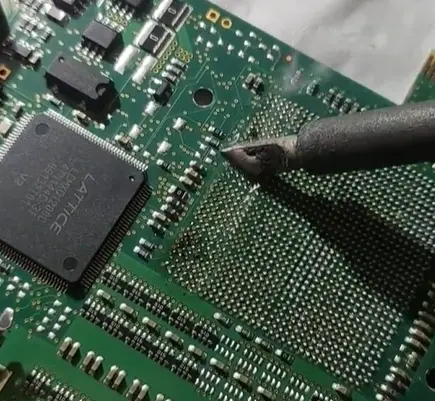

Removing the BGA

Clean and level the leftover solder on the PCB pads with a soldering iron. Use desolder braid and a flat-blade soldering iron tip as needed. When cleaning, be careful not to damage the pads or the solder mask.

Use a special cleaner to remove flux residues.

Dehydration (baking)

PBGA parts are sensitive to moisture. Before assembly, check if the part has absorbed moisture. If it is damp, perform a baking step to remove moisture.

Solder paste printing

Because other components are already on the board, use a special small BGA stencil. The stencil thickness and aperture size depend on ball diameter and pitch. After printing, inspect the print quality. If it is not good, clean the PCB and dry it, then reprint. For CSP with pitch below 0.4 mm, solder paste printing may be skipped. In that case, apply flux paste directly on the PCB pads.

Place the PCB in the reflow oven to remove the part. Run the reflow program. At the peak temperature, use a vacuum pick-up to remove the component. Let the PCB cool.

Pad cleaning

Use a soldering iron and desolder braid to clean and level solder residues on the PCB pads. Take care not to damage pads or solder mask.

Dehydration (again)

Because PBGA is moisture sensitive, check and bake any damp parts before assembly.

Solder paste printing (again)

As before, use a small BGA-specific stencil. The stencil thickness and aperture must match ball size and pitch. After printing, check print quality. If not acceptable, clean and dry the PCB and reprint. For CSP with pitch under 0.4 mm, you may skip printing and apply flux paste on the pads.

Placing the BGA

If the BGA is new, check its moisture content. If it is damp, bake it before placement.

Generally, removed BGA parts can be reused. But they must be re-balled first. Steps for placing a BGA:

A. Put the PCB with printed solder paste on the workbench.

B. Choose a proper nozzle and turn on the vacuum pump. Pick the BGA with the nozzle, align the BGA bottom with the PCB pads, lower the nozzle and place the BGA on the PCB, then turn off vacuum.

Reflow soldering

Set the reflow profile according to device size and PCB thickness. BGA reflow temperatures are generally about 15°C higher than for traditional SMD parts.

Inspection

BGA solder joint quality is usually inspected with X-ray or ultrasonic equipment. If you do not have those tools, use functional tests or experienced visual checks.

Hold the finished PCB up to a light and check the BGA edges. Look at whether light passes through, whether the gap between the BGA and PCB is even around the sides, whether the solder paste fully melted, whether the solder ball shape is regular, and the amount of ball collapse.

If the joint is not translucent, there may be bridging or solder balls between pads.

If ball shape is irregular or skewed, the temperature may be too low. Incomplete soldering can prevent the self-alignment effect during reflow.

Ball collapse level depends on reflow temperature, amount of paste, and pad size. With correct pad design, normal collapse after reflow is about 1/5 to 1/3 of the pre-reflow ball height. If collapse is too large, temperature is too high and bridging can occur.

If the gap between BGA edges and PCB is not uniform, the temperature around the package was not even.

Reballing (solder ball attachment) process

Remove residual solder on the BGA bottom pads and clean.

Use a soldering iron to remove leftover solder on the PCB pads. Use desolder braid and a flat soldering iron tip. Be careful not to damage pads or the solder mask.

Use special cleaner to remove flux residues.

Print flux on the bottom pads of the BGA

Often use high-viscosity flux for its stick and solder-aid properties. Ensure printed flux patterns are clear and do not spread. Sometimes solder paste is used instead of flux. If paste is used, the metal composition in the paste must match the solder ball metal.

For printing, use a small special BGA stencil. Stencil thickness and aperture must match ball diameter and pitch. After printing, check print quality. If not good, clean and reprint.

Choose solder balls

When choosing solder balls, consider ball material and diameter. PBGA solder balls normally use 63Sn/37Pb, the same alloy used in reflow solder. So choose balls with the same alloy as the device balls.

Ball size choice matters. If you use high-viscosity flux, choose balls the same diameter as the device balls. If you use solder paste, choose balls slightly smaller than device balls.

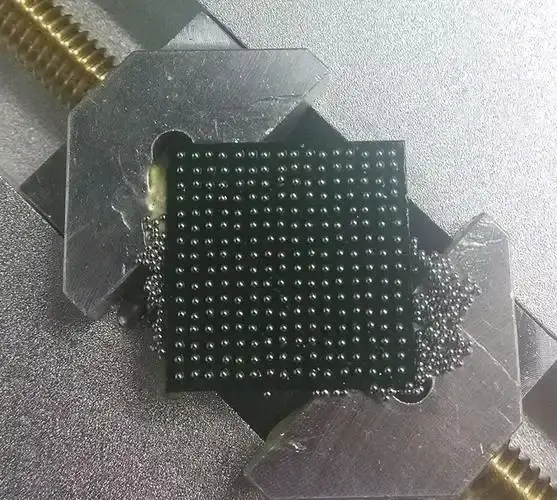

Ball attachment

There are several methods to attach balls:

A) Ball machine method

If you have a ball machine, choose a template that matches the BGA pad layout. Template aperture should be 0.05–0.1 mm larger than ball diameter. Evenly sprinkle balls on the template. Shake the ball machine so extra balls roll into the collection tray, leaving exactly one ball in each hole.

Place the template on the workbench. Pick up the printed flux or paste-coated BGA with a vacuum nozzle. Align and lower the BGA onto the balls in the template so that the paste or flux holds balls on the device pads. Use tweezers to hold the device frame and turn off vacuum. Place the device ball-side-up on the bench. Check for missing balls and add by tweezers if needed.

B) Template method

Place the flux or paste-coated BGA on the bench, flux facing up. Prepare a template that matches the BGA pad layout. Template aperture should be 0.05–0.1 mm larger than ball diameter. Support the template around the edges on shims so the distance to the BGA is equal to or slightly less than the ball diameter. Align under a microscope. Sprinkle balls evenly on the template. Remove extra balls with tweezers so one ball remains in each hole. Remove the template and check, replenishing any missing balls.

C) Manual placement

Place the flux or paste-coated BGA on the bench. Use tweezers or a pick-up pen like with ordinary SMD placement to place balls one by one.

D) Solder paste printing method

Make the stencil thicker and slightly enlarge the aperture. Print solder paste directly on the BGA pads. Surface tension will form solder balls after reflow.

Reflow

Run reflow to fix solder balls to the device.

Post-solder cleaning and handling

After reballing, clean the BGA device thoroughly. Then assemble and solder it as soon as possible. This prevents the solder balls from oxidizing and the device from absorbing moisture.

Summary

With continuous advances in technology, modern life is closely tied to electronics. Tiny mobile phones, small radios, portable computers, memory, hard drives, CD drives and high-definition TVs all demand miniaturization and light weight. To reach this, we must work on production processes and components.

SMT (Surface Mount Technology) matched this trend and laid the foundation for light, thin, short, and small electronic products. Since SMT matured in the 1990s, electronic product trends toward portability, miniaturization, networking and multimedia pushed assembly technology further. New high-density assembly methods emerged. BGA is one high-density assembly method that has reached practical use. This article introduced BGA assembly features and solder joint quality control.