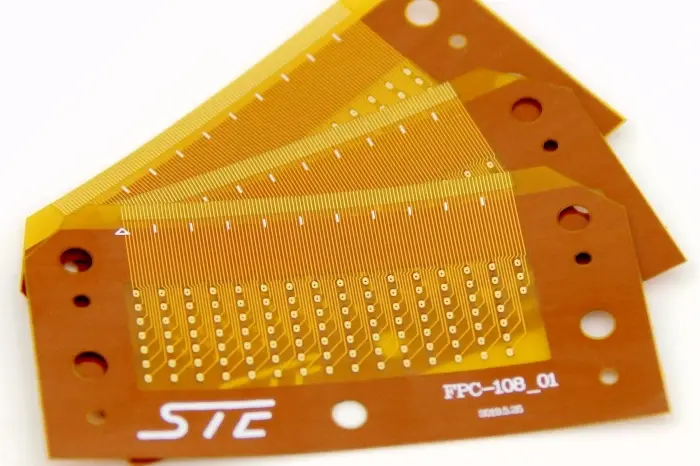

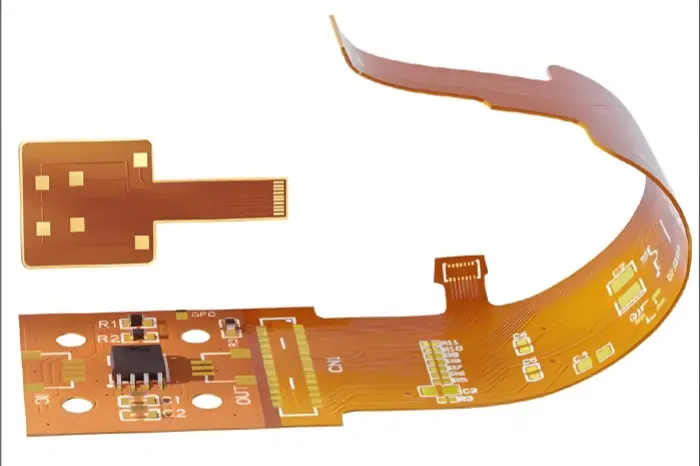

Flexible PCB is also called flexible printed circuit board, flex circuit, or flexible wiring board. As the name shows, it is a kind of circuit board that bends. It can fold, roll, stretch, and move in three dimensions. Flexible printed circuit boards are made on a thin film like polyimide or polyester. They give high reliability and very good flexibility.

Flexible printed circuits (FPC) trace their origins back to the 1950s, when researchers in the United States developed techniques to print and etch flat conductors onto flexible substrates as an alternative to traditional wiring harnesses. Makers used polyester or polyimide film as the base. These films make the board strong and bendable. By embedding circuits on thin plastic sheets, many small parts can be stacked in tight spaces. The result is a circuit that can bend, fold, and fit into compact shapes. Flexible circuits are light, take little space, cool well, and are easy to mount. They solved limits of old connection methods.

A flexible circuit has three main material groups. First is the insulating film. Second is the conductor. Third is adhesive. These parts work together to meet the need for smaller and mobile electronic devices. Flexible circuits let devices become denser, smaller, and more reliable.

Materials used in Flexible PCB

1. Insulating film

The insulating film forms the main base layer for the circuit. Adhesive is used to bond copper foil to the insulating film. In multilayer flex designs, the film is also used to bond inner layers.

The insulating film protects the circuit from dust and moisture. It also reduces stress when the board bends. The conductor layer is made from copper foil.

Some flex circuits use rigid parts made from aluminum or stainless steel. These rigid parts give dimensional stability. They give physical support for parts and wires. They also reduce stress. Adhesive bonds the rigid parts to the flexible circuit.

Another common material is a bonding layer that coats both sides of the insulating film. This bonding layer gives insulation and helps join layers. It can remove the need for some film layers and lets manufacturers bond many layers with fewer parts.

There are many insulating film types. The most used are polyimide and polyester. About eighty percent of flexible circuit makers in the US use polyimide film. About twenty percent use polyester film.

Polyimide is not easy to burn. It keeps its shape, resists tearing, and can stand soldering heat. Polyester, also called PET (polyethylene terephthalate), has physical traits close to polyimide. It has a lower dielectric constant and absorbs less moisture. But it does not resist high heat as well. Polyester melts at around 250°C and has a glass transition temperature (Tg) of about 80°C. This limits its use in products that need heavy board-edge soldering. In low temperature uses, polyester can act stiff. Still, polyester is good for phones and other products that do not face harsh conditions.

Polyimide films are often paired with polyimide or acrylic adhesives. Polyester films usually pair with polyester adhesives.

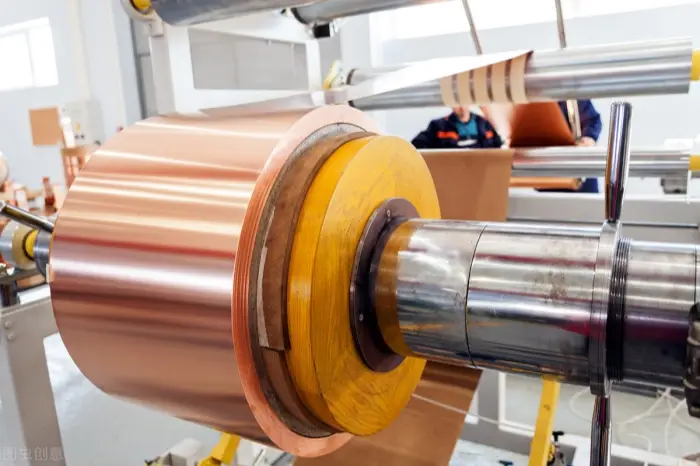

2. Conductor

Copper foil is a good fit for flexible circuits. Copper foil can be made by electro-deposition (ED) or by rolling and annealing (RA). One side of ED copper is shiny. The other side has a matte process surface. ED copper is bendable and can come in many thicknesses and widths. The matte side of ED copper often gets special treatment to make it stick better.

RA copper is both flexible and smooth. It can be stronger. RA copper is useful in designs that need repeated bending or dynamic flex.

3. Adhesive

Adhesives do more than bond the insulating film to the conductor. They can act as cover layers, protective coatings, or overlay layers. The main difference is how the layer is applied. The cover layer bonds to the insulating film and forms a laminated structure.

Screen printing is used for adhesive coverage and coating. Not all laminated structures use adhesives. Adhesive-free laminates make thinner, more flexible circuits. They also offer better heat transfer than adhesive-based laminates. Because there is no adhesive layer to block heat, heat moves through the circuit better. This lets adhesive-free flex operate in conditions where adhesive-based flex might fail.

Soldering steps for FPC (FPC soldering process)

Below are practical steps for hand soldering a PQFP chip and common SMD parts on flexible circuits. Use these steps as a clear guide. Follow safety and ESD rules too.

Before soldering, apply flux to the pads. Use an iron to treat the pads. This avoids bad tinning or pad oxidation. Chips usually do not need pre-work.

Use tweezers to carefully place the PQFP chip on the PCB. Do this to avoid bending or breaking the leads. Align the chip with the pads. Make sure the chip points the right way. Heat the iron to above 300°C. Put a little solder on the iron tip. Press down the aligned chip with a tool. Add a small amount of solder to two diagonal pins. Hold the chip and solder the two diagonal pins. This will fix the chip in place. After those two pins are soldered, check alignment. If needed, move or remove and re-place the chip.

When you start soldering all pins, add solder to the iron tip. Apply flux to all pins to keep them wet. Touch the iron tip to the end of each pin until you see solder flow into the pin. Keep the iron tip parallel to the pins during soldering. This helps stop pins from bridging due to too much solder.

After soldering all pins, use flux to wet all pins and clean the solder. Remove extra solder to remove shorts and bridges. Finally, use tweezers to inspect for bad solder joints. When done, clean the board. Use alcohol and a stiff brush, then wipe along the pin direction until the solder residue is gone.

SMD resistors and capacitors are easier. Place the part on a pad. Then place one end on the pad and hold it with tweezers. Solder one end first. Check placement. If it is aligned, solder the other end.

Key differences between rigid PCB and flexible circuit

Rigid PCBs are what people usually think of as circuit boards. They use conductors and other parts on a non-conductive board. The non-conductive board often contains glass. The glass makes the board strong and stiff. Rigid PCBs give good support for parts and good heat resistance.

Flexible PCBs also have conductive traces on a non-conductive base. But the base is flexible, like polyimide. A flexible base lets the circuit bend, handle vibration, cool well, and fold into many shapes. Because of these shapes, flex circuits are now common in compact and new electronic designs.

Besides the base material and stiffness, other big differences include:

Conductor choice: Flex often uses softer RA copper instead of hard ED copper. This helps if the circuit must bend without cracking.

Manufacturing: Flex makers do not use soldermask like rigid PCBs. They use coverlay or covercoat to protect bare traces.

Cost: Flex circuits usually cost more than rigid boards. But a flex board can let engineers shrink a product. That can lower the total product cost because a smaller product may cost less to make or ship.

How to choose between rigid and flexible PCBs

Both types can work in many products. Some uses benefit more from one type. For example, rigid PCBs make sense in larger products like TVs and desktop PCs. Compact products like phones and wearables often need flex circuits.

When you choose, think about:

What your product needs to do.

What the industry normally uses for similar products.

How using one type might change costs or assembly.

If your device needs folding, bending, or space saving, pick flex. If you need low cost and high mounting strength for large parts, choose rigid.

Stiffeners for flexible PCBs

Stiffeners are also called reinforcement plates, support plates, or strengthening ribs. They are used in electronics to control flex. Stiffeners solve the problem that flex boards can be too bendy. They make plug-in areas stronger and help assembly.

Common stiffener types:

Stainless steel stiffeners

Aluminum stiffeners

Polyester stiffeners

Polyimide stiffeners

Glass fiber stiffeners

PTFE (Teflon) stiffeners

Polycarbonate stiffeners

Handling rules for polyimide (PI) stiffeners:

Bake PI stiffeners at 80°C for 30 minutes before use.

Work in a clean room at about 25°C and 65% relative humidity if you can.

Use fresh-cut PI stiffeners soon. If they sit more than one day, seal them well.

Clean the interface where the FPC meets the stiffener before bonding.

Use correct bonding and press conditions when using different presses.

After curing, wait for the jig to cool before opening and removing the part.

Do not cool PI stiffeners quickly after lamination. Remove the part onto a slow-heat carrier like glass fiber cloth if you must. If you use a platen press, wait until the product cools to room temperature.

How to prevent dents and cracks in flexible PCBs

The neutral bending axis of a flex circuit may not be centered in the stack. Proper handling helps stop dents and cracks.

Flexible PCBs are like mechanical parts as well as electrical parts. The trace layout must make the whole circuit strong. Unlike a rigid board, a flex board can bend, twist, and fold to fit inside the final product. If the bend goes beyond a point, the copper is put under strong tension. That can break the flex or make dents.

Flex gives designers options that rigid boards do not. Even when flex is right for the job, that does not mean copper traces will never fail. Copper also has limits on the stress it can take.

You need to watch many things, especially when the product will see dynamic bending (bending while in use) or when it must fold into small housing spaces. Precision is important to avoid crack.

Design considerations to improve

flex and bending

Below are clear design ideas to increase life and reliability.

Know the stress points and bend radius

Know the limits for bending, folding, and twisting. For single-sided flex, if the stretch or squeeze exceeds the bend radius or stress point, the copper will crack. Always work inside these limits.

Neutral axis

For dynamic flex use, single-sided flex designs are best. Single-sided gives the copper room to sit near the structure center. In this layout, the copper is not strongly compressed or stretched during dynamic bending.

Thinner is better

Thinner stacks bend more easily. They have a smaller inner bend radius and less stress on the outer layer. For parts that bend a lot, use thinner copper and thinner dielectric layers.

I-beam layout

I-beam means copper or dielectric layers overlap directly on both sides. This makes the fold area stronger. Because the inner layer compresses, the outer layer sees more stretch. To reduce this, offset the traces on opposite sides.

Sharp bends or folds

Many flex boards are designed to fold. A well-made board can take the first fold or twist. But repeatedly folding a creased area is not good. The copper will break over time. It is not recommended. Use design tricks like rounded corner traces in the fold area.

Other tips to avoid cracking:

Use soldered or tinned trace paths.

Use RA copper or ED copper with controlled grain direction.

Use a covering polyimide film in the bend area.

Use stiffener ribs on the bottom and a cover layer on the top.

Other practical design and process notes

When you load parts, keep traces away from holes and sharp edges. This lowers break risk.

Use round pad shapes and add fillets on traces near bends.

Keep vias out of high-stress bend zones. If you must place vias, use reinforcement.

Use radiused corners on traces and pads. Right angles concentrate stress and can cause cracks.

When you route traces across a fold, try to route them perpendicular to the fold axis when possible. This lowers tensile stress.

For repeated motion, try to use a flex-to-board transition that keeps the bend in a free area with no parts or vias.

Assembly handling and environmental notes

Store polyimide and other materials in dry, sealed bags. Moisture can harm adhesives and cause delamination.

Keep work areas clean. Dust and oils harm bonding.

For reflow soldering, follow the material’s time-temperature limits. Polyimide handles high heat, but polyester does not.

When you use adhesives, follow cure curves and cooling steps. Cooling too fast can cause stress and warpage.

Use ESD protection when you handle flex circuits. Some circuits have sensitive ICs.

Common applications of flexible PCBs

Flexible circuits are popular in many products:

Mobile phones and tablets

Cameras

Wearable devices

Medical devices and sensors

Automotive sensors and dashboard parts

Aerospace and military electronics

LED lighting and displays

Connectors and cable assemblies

Their main benefits are small size, light weight, and the ability to fit in odd shapes.

Advantages and limits of flex circuits

Advantages:

Save space and reduce weight.

Allow moving or folding parts.

Lower connector needs because flex can be wired between boards.

Good thermal performance when designed right.

Improved reliability in many dynamic uses.

Limits:

Cost is higher than simple rigid PCBs.

Handling requires more care.

Some materials cannot withstand high soldering heat.

Dynamic bending short-life risks if design is wrong.

Testing and quality checks

To ensure reliability:

Use bend testing to check dynamic bend life.

Use thermal cycling to test resistance to temperature change.

Inspect with X-ray or microscope for hidden cracks.

Use pull tests on glued stiffeners and connectors to check hold strength.

Check impedance and continuity for signal lines.

Final notes and quick tips

Choose polyimide for higher heat and higher reliability. Choose polyester when lower cost and lower heat are okay.

For dynamic flex, use single-sided thin stacks and RA copper.

Add stiffeners at connector areas to help assembly.

Keep bend radii large when you can. Larger radii give longer life.

If you see dents or cracks early, review the bend location and the stack. Change copper type, thickness, or add a coverlay.

Make sure assembly steps match the material limits. For example, do not use high-temperature solder processes on polyester-based flex.

Flexible PCB— Frequently Asked Questions

Answer: A flexible PCB (FPC) is a bendable circuit board made on a thin film such as polyimide (PI) or polyester (PET). It can fold, roll, and fit in three-dimensional space. It saves space and reduces the need for connectors.

Answer: PI (polyimide) resists high heat, tears less, and is more reliable. Use PI when you need high-temperature reflow or harsh environments. PET (polyester) costs less, has lower dielectric constant, and absorbs less moisture, but it does not resist high heat well. Use PET for phones and other mild-environment products.

Answer: Copper foil is common. There are ED (electro-deposited) copper and RA (rolled-annealed) copper. RA copper is better for designs that bend often.

Answer: A stiffener is a reinforcement piece (for example PI, metal, or fiberglass). Use a stiffener to strengthen connector or solder areas, to make assembly easier, or to protect an interface.

Answer: Control the bend radius in the design. Do not place parts or many vias in the bend area. Use the right copper thickness and dielectric thickness. Add stiffeners or coverlay at key places. Do not fold the same crease many times.

Answer: Use a rule of thumb: the bend radius = (ratio) × total flex thickness. For a single-layer static bend (bent once and kept), a common guideline is 10 × thickness. For a single-layer dynamic bend (bends many times), a common guideline is 100 × thickness.

Example: if the flex is 0.20 mm thick, then static radius = 0.20 × 10 = 2.0 mm, and dynamic radius = 0.20 × 100 = 20.0 mm.

Note: Guidelines vary by layer count, materials, and use. Check your contract manufacturer or IPC / supplier DFM rules for exact limits.

We typically produce and dispatch PCB samples within 48 hours after order confirmation, final artwork (Gerber) approval, and payment. Shipping time is separate and depends on the courier and destination.